|

| |

TM 9-2320-364-34-4

26-9

(23)

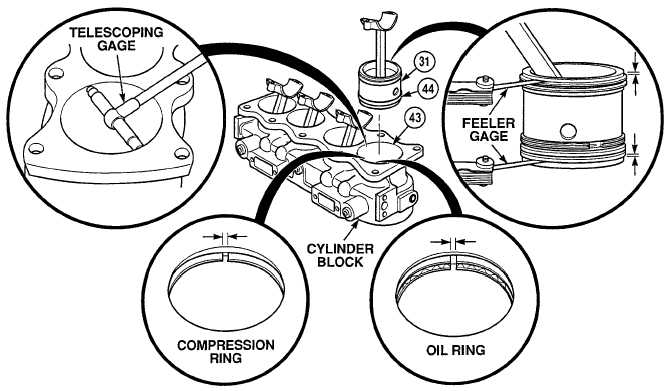

Measure piston (31) outside diameter. Measure cylinder bore (43) inside diameter. Piston to bore

clearance should not exceed 0.008 in. (0.203 mm). Replace pistons and cylinder block if clearance is

exceeded.

(24)

Inspect bores (43) for out-of-round or taper. Bores must not be out-of-round more than 0.0005 in.

(0.0127 mm). Bores must not taper more than 0.001 in. (0.025 mm) from top to bottom of bore. Replace

cylinder block if limits are exceeded.

(25)

Inspect piston rings (44) for cracks or wear.

NOTE

Tag and mark all piston rings upon removal.

(26)

Remove piston rings (44) from piston (31).

(27)

Position compression ring in cylinder bore (43) and measure end gap clearance. If clearance exceeds

0.017 in. (0.432 mm), replace piston rings. Repeat for all pistons.

(28)

Position oil ring in cylinder bore (43) and measure end gap clearance. If clearance exceeds 0.0055 in.

(0.1397 mm), replace piston rings. Repeat for all pistons.

(29)

Install all piston rings (44) on pistons (31).

|