|

| |

TM 9-2320-364-34-4

28-34

28-7. HOIST ASSEMBLY REPAIR (CONT).

(1)

Clean all metal parts in drycleaning solvent.

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only with

effective chip guarding and personal protective equipment (goggles/shield, gloves, etc).

Failure to comply may result in injury to personnel.

(2)

Dry all metal parts with compressed air. Allow bearings to air dry.

(3)

Inspect each part for nicks, burrs, scratches or dents.

(4)

Replace damaged parts.

c.

Assembly.

NOTE

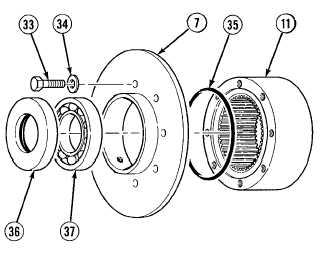

Large slot in bearing faces down.

(1)

Install bearing (37) and oil seal (36) in drum

end (7).

Adhesives, solvents, and sealing

compounds can burn easily, can

give off harmful vapors, and are

harmful to skin and clothing. To

avoid injury or death, keep away

from open fire and use in

well-ventilated area. If adhesive,

solvent, or sealing compound

gets on skin or clothing, wash

immediately with soap and water.

(2)

Apply adhesive to drum end (7) and install

preformed packing (35) on drum end (7).

(3)

Apply sealing compound to threads of eight

screws (33).

(4)

Install drum end (7) on ring gear (11) with

eight washers (34) and screws (33). Tighten

screws to 216 lb-in (24 N.m).

|