|

|||

|

|

|||

|

Page Title:

Check/Adjust Tire Air Pressure. (Cont) |

|

||

| ||||||||||

|

|

TM 9-2330-385-14

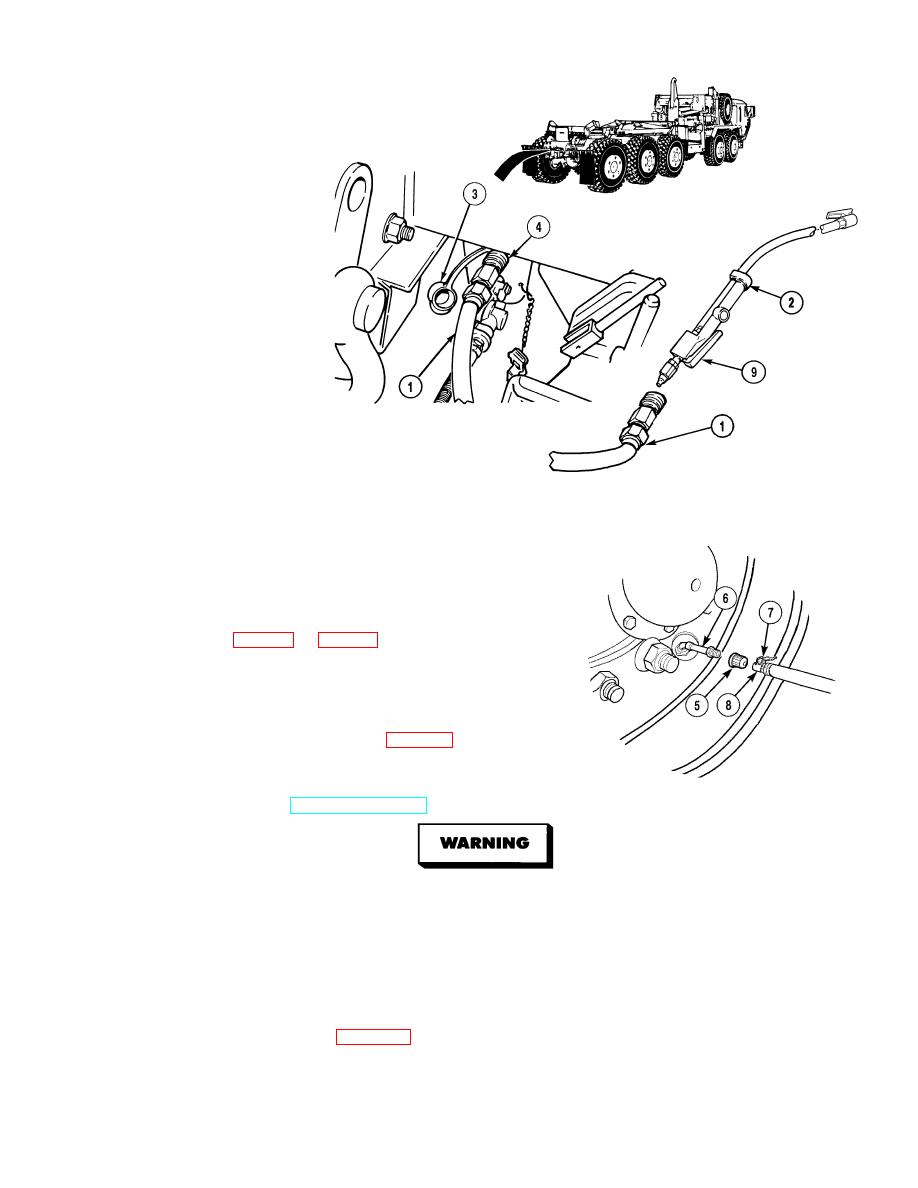

(8)

If tire is underinflated or overinflated or if

the wheel or tire has obvious damage or

suspected damage, stand out of trajectory

range. Remove inflation gage (2) from air

hose (1) and press handle (9) until all air

pressure has exhausted from inflation gage.

When tire is completely deflated, remove

from trailer and take to Unit Maintenance for

disassembly and repair. Install spare tire on

trailer (Para 3-4 and Para 3-5).

(9)

If tire is not underinflated or overinflated and

the wheel or tire does not have obvious

damage or is not suspected of damage, stand

out of trajectory and inflate or deflate until

proper pressure is attained (see Table 3-5).

Press in latch handle (7) and pull air chuck (8)

from valve stem (6). Install valve cap (5).

(10)

Shut off engine (TM 9-2320-364-10).

Hold end of air hose when disconnecting from quick-disconnect coupling. Air hose is under

pressure and can fly out at fast rate of speed causing injury to personnel.

(11) Remove air hose (1) from air coupler (4) and install cover (3) on air coupler (4).

(12) Remove inflation gage (2) from air hose (1). Stow air hose and inflation gage in PLS truck BII stowage

box.

b.

Follow-On Maintenance:

Remove wheel chocks, (Para 2-20).

END OF TASK

3-19/(3-20 blank)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |