|

|||

|

|

|||

|

Page Title:

SERVICE BRAKES ON ALL AXLES DO NOT APPLY OR APPLY SLOWLY. (Cont) |

|

||

| ||||||||||

|

|

TM 9-2330-385-14

NOTE

Trailer air system pressure must be 125

S

5 psi (862 34 kPa) to begin

troubleshooting the brake system. If the

air system pressure cannot be maintained,

refer to Air System Troubleshooting.

Air lines and valves listed in this

S

troubleshooting procedure are illustrated

and located in FO-2.

VISUAL INSPECTION

(1) Inspect air lines 2255, 2660, 2260,

2639, 2638 and 2637 for crimps.

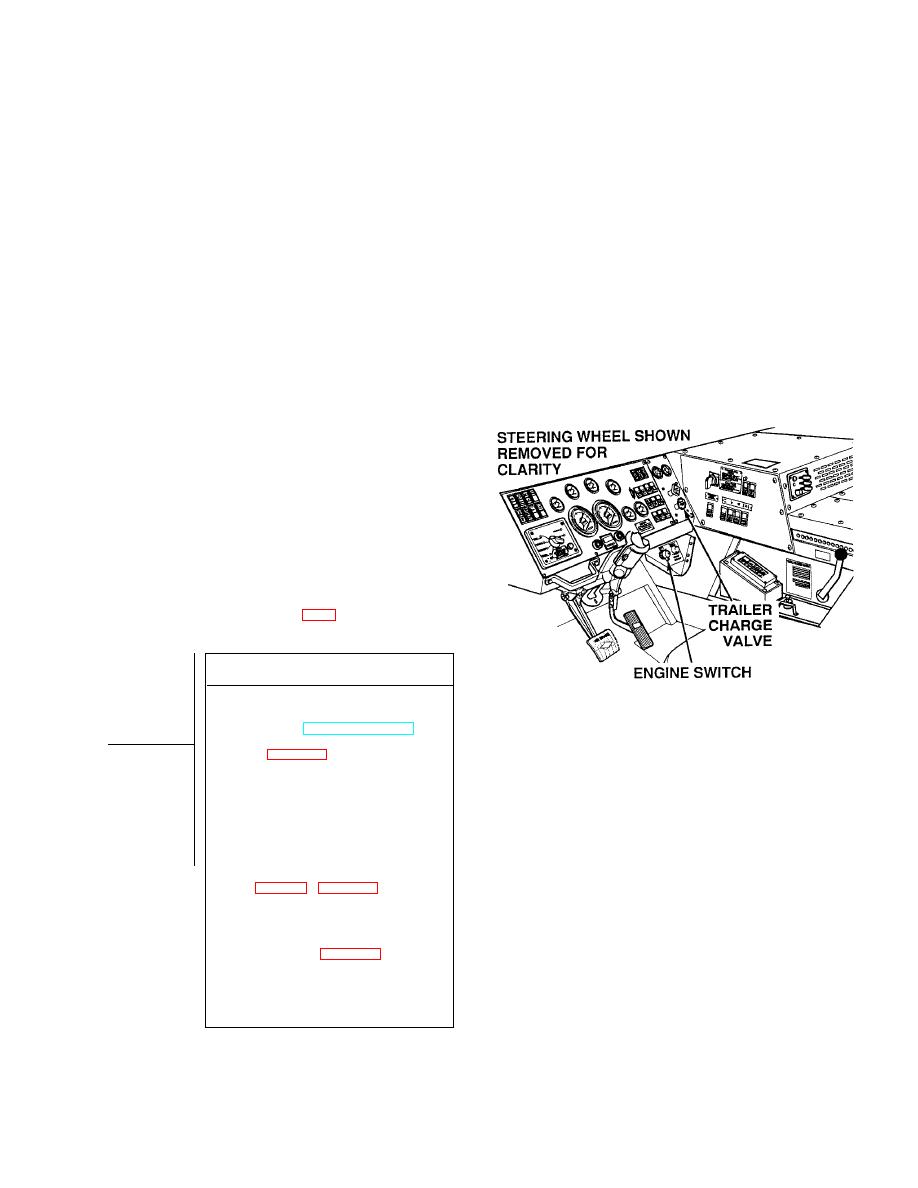

(2) Start engine (TM 9-2320-364-10).

(3) Push in trailer charge valve in

truck (Para 2-22).

(4) While assistant fully applies brake

pedal, listen to air lines, fittings, load

sensor valve and quick release valve

for leaks.

(a) If fittings leak and are loose,

tighten fittings.

(b) If hose(s) leaks, perform Steps (5)

and (6) below and repair or

replace hose(s) (see schematic

(c) If any of the items listed above

leak, perform Steps (5)

and (6) below and replace them

according to maintenance

procedures (Chapter 4).

(d) If all of items listed above are OK,

go to Step (2) of this Fault.

(5) Pull out trailer charge valve in truck.

(6) Turn OFF ENGINE switch.

4-273

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |