|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2330-385-14

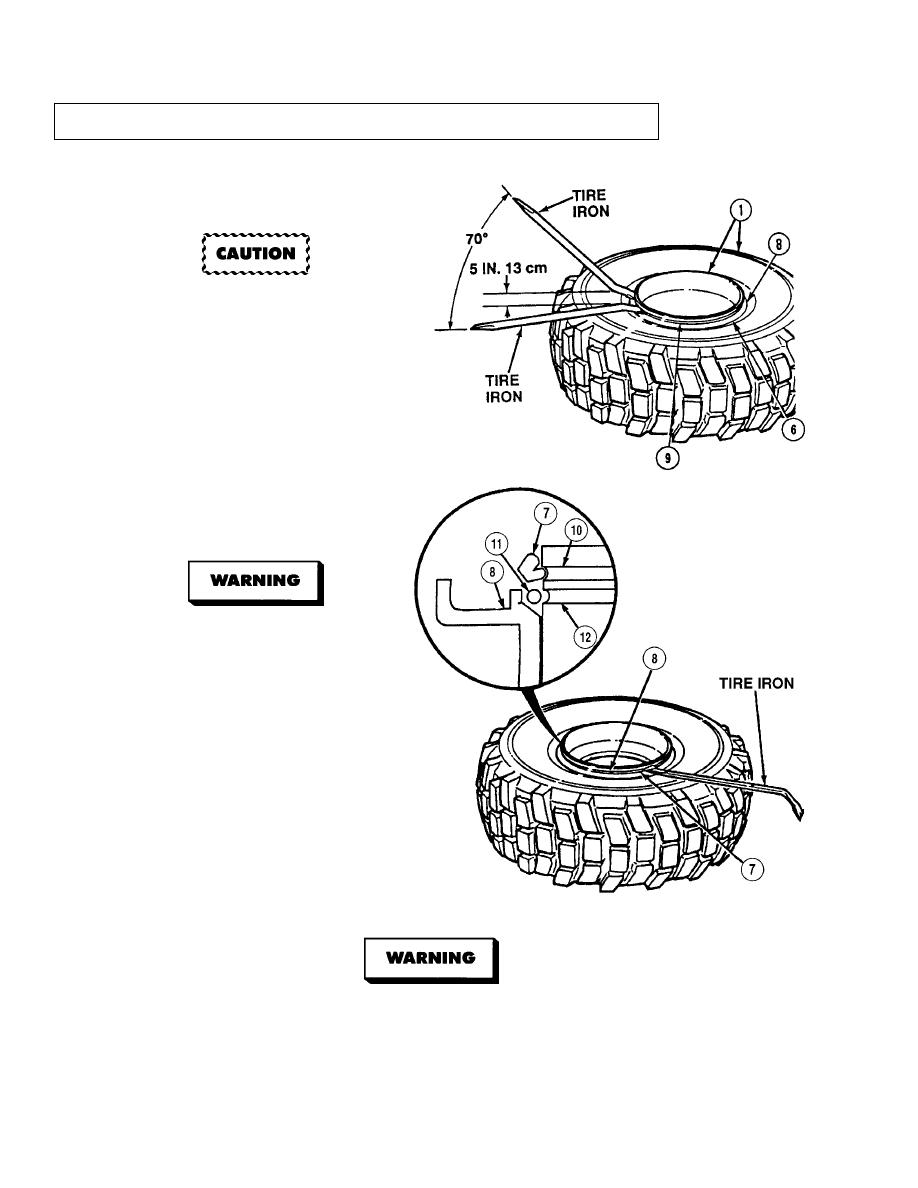

4-56. WHEEL/TIRE ASSEMBLY REPAIR (THREE-PIECE WHEEL)(CONT).

(5)

Insert the goose-necked end of two tire irons

between tire (6) and side ring (8)

approximately five in. (13 cm) apart.

Ensure not to tear the chafer

fabric when unseating the tire

bead or damage to tire may

result.

Use tire lubricant as necessary

to avoid damaging tire beads

or bead seats during

demounting.

(6)

Pry both tire irons outward and sideways

through an arc of about 70 degrees. Leave

one tire iron in position and place the

second tire iron approximately five in. (13

cm) away. Repeat this procedure until tire

bead (9) is completely unseated.

Lock ring is under tension. If lock

ring breaks loose it could cause

injury to personnel. Keep hands

and fingers away from

lock ring when removing.

NOTE

Ensure side ring and tire side wall

are depressed below lock ring and

preformed packing.

(7)

Using tire iron, pry under lock ring (7)

and remove from lock ring groove (10).

(8)

Remove preformed packing (11) from

preformed packing groove (12). Cut in

two and discard preformed packing.

(9)

Remove side ring (8) from tire (6).

Wheel/tire assembly weighs 425 lbs (193 kg). Use suitable lifting device to lift wheel/tire

assembly and prevent possible injury to personnel.

(10)

Using lifting device, turn wheel/tire assembly (1) over on blocks so flange is facing up.

(11)

Repeat Step (7) to unseat tire bead (9) from wheel/tire assembly (1).

4-510

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |