|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-3990-206-14&P

c.

Assembly.

CARC paint contains

isocyanate (HDI) which is

highly irritating to skin and

2

respiratory system. High

9

7

concentrations of HDI can

6

produce symptoms of itching

and reddening of skin, a

burning sensation in throat and

nose and watering of the eyes.

In extreme concentrations,

HDI can cause cough,

shortness of breath, pain

8

during respiration, increased

1

sputum production, and chest

tightness. The following

3

precautions must be taken

whenever using CARC paint:

4

ALWAYS use air line respirators when using CARC paint unless air sampling shows

exposure to be below standards. Use chemical cartridge respirator if air sampling is

below standards.

DO NOT let skin or eyes come in contact with CARC paint. Always wear protective

equipment (gloves, ventilation mask, safety goggles, etc.).

DO NOT use CARC paint without adequate ventilation.

NEVER weld or cut CARC-coated materials.

DO NOT grind or sand painted equipment without high-efficiency air purifying

respirators in use.

BE AWARE of CARC paint exposure symptoms; symptoms can occur a few days after

initial exposure. Seek medical help immediately if symptoms are detected.

Unsafe welding practices can cause serious injury from fire, explosions, or harmful agents.

Allow only authorized personnel to weld or cut metals, and follow safety precautions TC

9-237. Protective clothing and goggles must be worn; adjustable protective equipment

used, and suitable fire extinguisher kit near by; and requirements of TC 9-237 strictly

followed.

Flatrack must be removed from truck and trailer prior to any welding being performed.

(1)

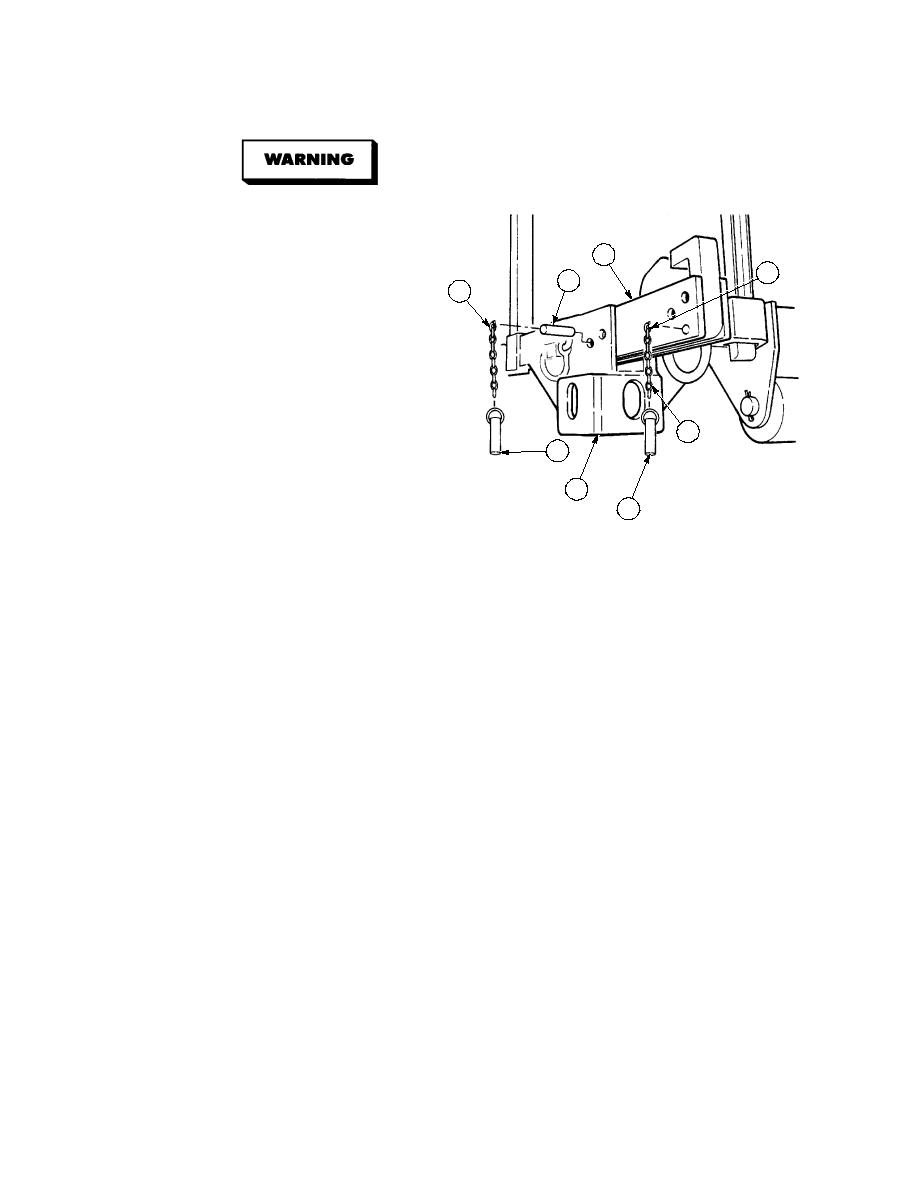

Install extension (2) on flatrack (3) with pivot pin (7).

NOTE

Weld pivot pin on outside only. Do not weld inside.

(2)

Refer to TC 9-237 and weld pivot pin (7) on flatrack (3).

(3)

Install chain (8) on pin (4).

(4)

Refer to TC 9-237 and weld chain (8) on pin (9).

(5)

Install chain (6) on pin (1).

(6)

Refer to TC 9-237 and weld chain (6) on pivot pin (7).

5-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |