|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-3990-206-14&P

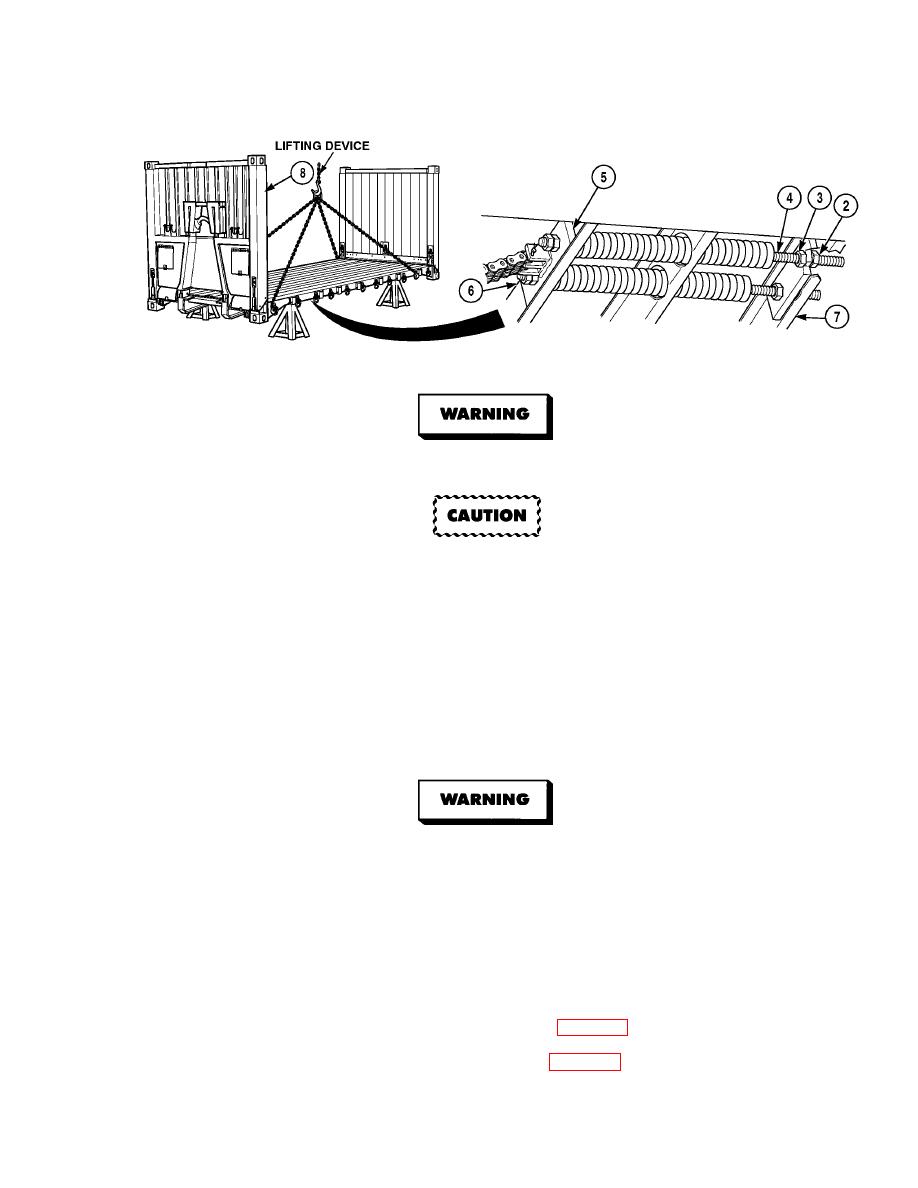

Spring adjustments must be made with walls raised and pinned. Failure to comply may

result in injury or death to personnel.

Nuts on threaded rods must be adjusted evenly on all spring assemblies to ensure equal

tension on springs. Failure to comply may result in damage to equipment.

NOTE

For front wall spring adjustment, Perform Steps (3) through (16).

For rear wall spring adjustment, Perform Steps (17) through (33).

(3)

Loosen four nuts (2) and jam nuts (3) on threaded rods (4) until clevis (5) can be separated from

crossmember (6).

(4)

Tighten four nuts (2) on threaded rods (4) until clevis (5) contacts crossmember (6).

Adhesives, solvents and sealing compounds can burn easily, can give off harmful vapors

and are harmful to skin and clothing. To avoid injury or death, keep away from open fire

and use in well-ventilated area. If adhesive, solvent or sealing compound gets on skin or

clothing, wash immediately with soap and water.

(5)

Apply sealing compound to threads of four threaded rods (4) on spring side of crossmember (7).

(6)

Tighten four jam nuts (3) on threaded rods (4) until jam nuts contact crossmember (7).

(7)

Tighten four nuts (2) on threaded rods (4) to 200 lb-ft (271 N⋅m).

(8)

With the aid of an assistant, lower front wall (8). Refer to Para 7-10.

(9)

With the aid of an assistant, raise front wall (8). Refer to Para 7-10.

9-39

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |