TM 5-3990-263-13&P

0035

Table 1.

Operator Preventive Maintenance Checks and Services - Continued

ITEM TO BE

EQUIPMENT

ITEM

CHECKED OR

NOT READY/

NO.

INTERVAL

SERVICED

PROCEDURE

AVAILABLE IF:

Position remote control WINCH switch (Figure 15, Item

11) to IN until winch cable hook (Figure 15, Item 12) is

in saddle (Figure 15, Item 13).

Position HOOK ARM switch (Figure 15, Item 8) to load

position until hook arm cylinders (Figure 15, Item 9) are

extended approximately 6 inches (15 cm).

Position MAIN FRAME switch (Figure 15, Item 10) to

LOAD until main frame is in stowed position.

Position HOOK ARM switch (Figure 15, Item 8) to LOAD

until hook arm is in stowed position.

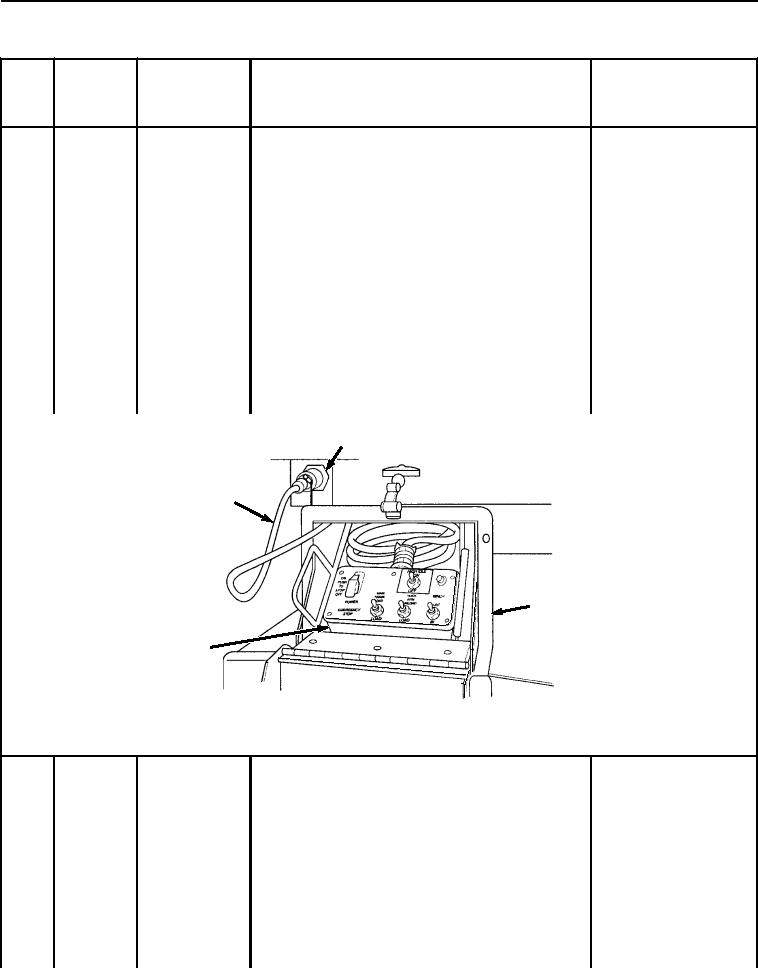

Disconnect remote control cable (Figure 16, Item 3) from

LHS receptacle (Figure 16, Item 4), and stow cable

(Figure 16, Item 3) and remote control unit (Figure 16,

Item 1) in stowage box (Figure 16, Item 2).

4

3

2

1

Figure 16. Disconnect Remote Control Unit.

NOTE

16

During

Front Pin Locks

This check must be made while bridge bay is

being loaded onto BAP.

Ensure BAP front pin locks (Figure 17, Item 1) are

Front pin locks do not

adjusted properly:

engage bridge bay front

pins.

If BAP front pin locks (Figure 17, Item 1) work

properly but do not engage bridge bay front

pins (Figure 17, Item 2), notify Field

maintenance to adjust BAP front pin locks.

If BAP front pin locks (Figure 17, Item 1) work

properly and do engage bridge bay front pins

03/15/2011Rel(1.8)root(pmcswp)wpno(I04003)