|

| |

TM 9-2320-364-34-3

16-126

16-18. SWING DRIVE GEAR REDUCER REPLACEMENT (CONT).

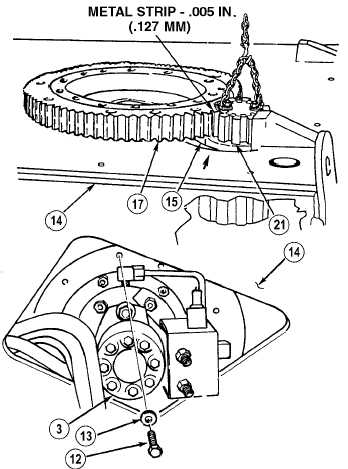

NOTE

The .005 in. (.127 mm) metal

strip must be positioned around

tooth on spur gear and between

spur gear and bearing gear to

obtain .010 in. (.254 mm)

backlash.

(12)

Position .005 in. (.127 mm) metal strip

around tooth of spur gear (21) and position

spur gear (21) with metal strip on bearing

gear (17).

Unsafe welding practices can

cause serious injury from fire,

explosions, or harmful agents.

Allow only authorized personnel

to weld or cut metals, and follow

safety precautions in TC 9-237.

Protective clothing and goggles

must be worn; adequate

protective equipment used, a

suitable fire extinguisher kept

nearby; and requirements of

TC 9-237 strictly followed.

(13)

Tack weld spacer ring (15) to subframe

assembly (14) in accordance to TC 9-237.

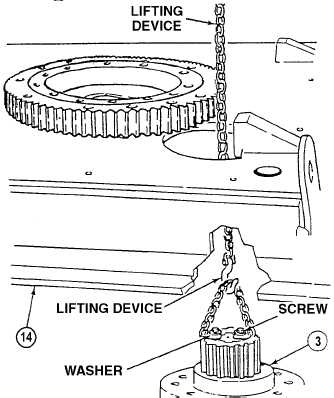

Swing drive gear reducer weighs

140 lbs. (64 kg). Attach suitable

lifting device prior to removal to

prevent possible injury to

personnel.

(14)

With the aid of an assistant and using lifting

device, remove nine screws (12), washers

(13) and swing drive gear reducer (3) from

subframe assembly (14).

(15)

Remove two screws, washers and chain

from swing drive assembly gear reducer

(3).

|