|

| |

TM 9-2320-364-34-4

28-19

This task covers:

a. Disassembly

b. Cleaning/Inspection

c. Assembly

INITIAL SETUP

Materials/Parts

Grease (Item 22, Appendix B)

Solvent, Drycleaning (Item 68, Appendix B)

Equipment Condition

Tension link on clean work surface

Tools and Special Tools

Tool Kit, General Mechanic’s

(Item 240, Appendix F)

Compressor Unit, Air (Item 35, Appendix F)

Gage Set, Telescoping (Item 69, Appendix F)

Gloves, Chemical Oil Protective

(Item 81, Appendix F)

Goggles, Industrial (Item 83, Appendix F)

Gun, Airblow (Item 86, Appendix F)

Micrometer, Outside, Caliper, Set

(Item 139, Appendix F)

Press, 60 Ton (Item 164, Appendix F)

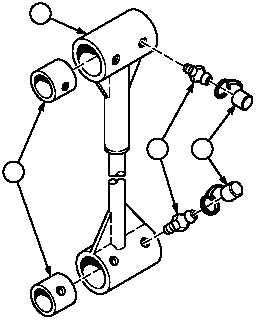

28-4. TENSION LINK REPAIR.

a.

Disassembly.

(1)

Remove four grease caps (1) and lube

fittings (2) from tension cylinder (3).

NOTE

Perform Step (2) if bushings

are damaged.

There are two different types

of weld head configurations.

If there is a shoulder machined

in the weld head between the

bushings preventing the

bushings from being pressed

out, bushings must be tapped

out from inside of weld head.

If there is not a shoulder

between bushings, both

bushings can be pressed out

from one side.

(2)

Use hammer and brass drift to remove four

bushings (4) from tension link (3).

2

1

3

4

|