|

|||

|

|

|||

|

Page Title:

Table 4-1. Unit Maintenance Preventive Maintenance Checks and Services - CONT. |

|

||

| ||||||||||

|

|

TM 9-2330-385-14

Table 4-1. Unit Maintenance Preventive Maintenance Checks and Services - CONT.

Item

Interval

Item to Be

Procedure

Not Mission

No.

Inspected

Capable If:

NOTE

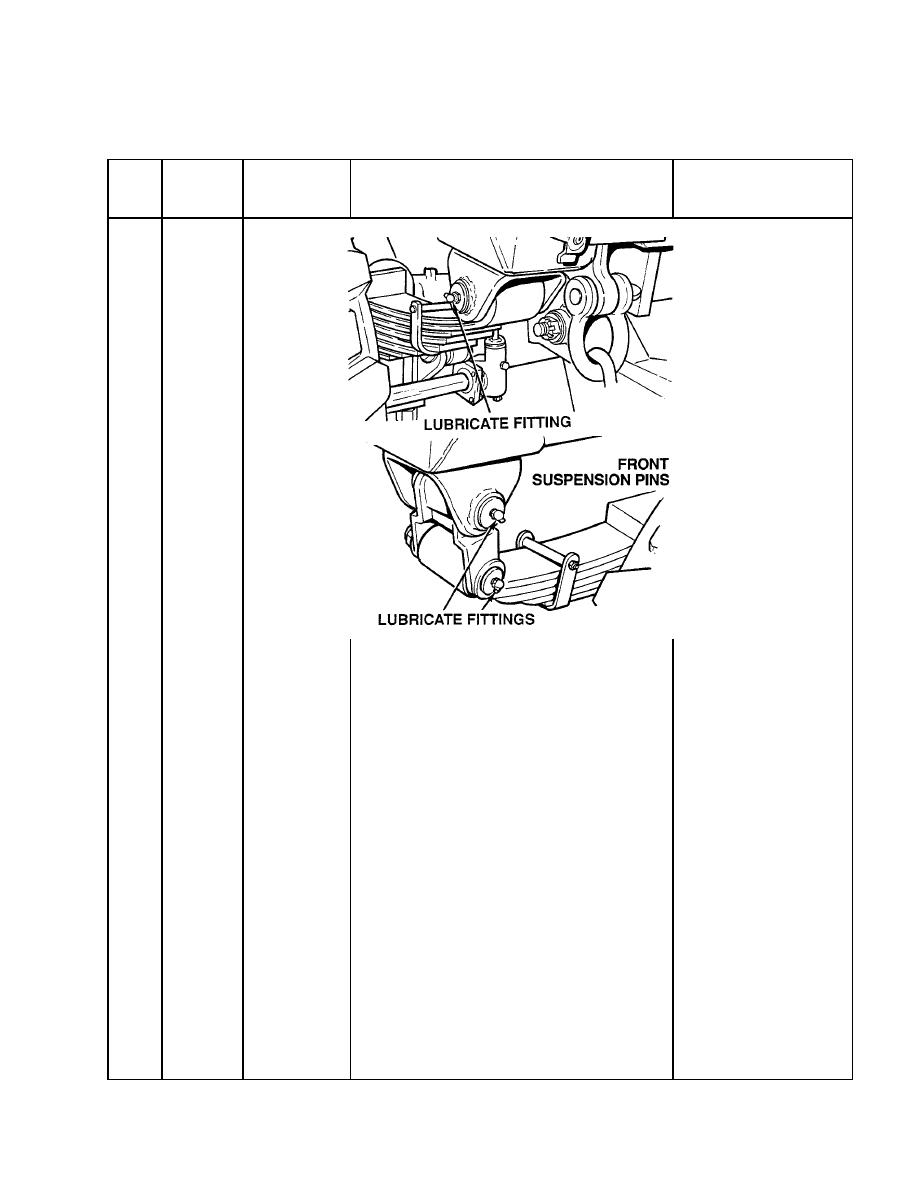

If an air-operated grease gun does not purge

D

the fitting, use a hand-operated grease gun.

If the part does not purge, remove fitting and

clean, install fitting and grease again. If part

still does not purge, refer to maintenance

task for that component.

When using a grease gun, apply lubricant to

D

the fitting until clean lubricant squeezes out

of the part being lubricated.

If suspension pin does not accept grease,

D

relieve load on suspension pin by jacking

trailer up by frame as close to suspension pin

as possible. If suspension pin still fails to

accept grease, notify Direct Support

Maintenance to remove suspension pin and/

or bushing and replace if necessary.

16

Semi-

Front

Lubricate all suspension pins with GAA every

Fittings will not purge

Annual

suspension

3,000 miles (4,827 km) or semi-annually,

old lubricant out of

pins

whichever comes first.

component.

4-15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |