|

| |

TM 9-2320-364-20-2

2-911

Remove all jewelry such as rings, dog tags, bracelets, etc. If jewelry contacts positive electrical circuits,

a direct short may result in instant heating of tools, damage to equipment, and injury or death to personnel.

Circuit breakers CB5, CB6, CB12, CB20, CB22, CB23 and relays R3, R13 - R19, R26, R28, R32, R33 are

always electrically hot and can cause severe injury to personnel. Non-metallic tools shall be used

when removing relays.

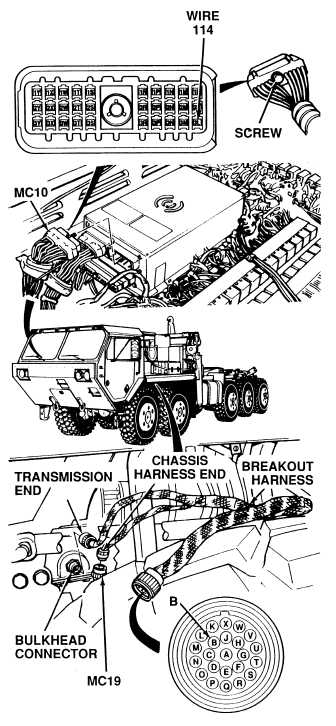

(1) Remove 15 screws and two

ECB covers.

(2) Loosen screw and disconnect

connector MC10 from ATEC ECU.

(3) Connect transmission connector

MC19 to breakout harness

chassis end connector.

(4) Is there continuity between connector

MC10 and breakout harness

connector on the solenoid harness

input and output wires listed in

(Table 2-31)?

(a) If there is no continuity, repair

wire(s) (Table 2-31)

(see schematic Fig 2-22) or notify

DS Maintenance.

(b) If there is continuity,

cab/transmission harness wires

are OK.

(5) Disconnect breakout harness

transmission and chassis end

connectors from transmission

bulkhead and MC19 connector.

(6) Connect transmission connector

MC19 to transmission bulkhead

connector.

(7) Install connector MC10 to ATEC ECU

and tighten screw.

(8) Install two ECB covers and 15 screws.

(9) Install left rear skirt on underside of

fender (Para 17-34).

CONTINUITY TEST

NOTE

Table 2-31 lists ECU and transmission bulkhead connectors

MC10 and MC19 and the solenoid wires and connector terminals

used as test points for the following procedures.

Table 2-31. ECU and Transmission Bulkhead

Connectors.

ATEC WIRE HARNESS

SOLENOID WIRES TEST POINTS

Solenoid

Conn.

(Code No.)

J(41)

F(42)

D(43)

C(44)

B(45)

A(46)

G(51)

E(52)

H(53)

ECU Conn. MC10

Term. (Wire No.)

Bulkhead

Term. (Wire No.)

3L(114)

3M(111)

2T(120)

1W(105)

2T(120)

1S(110)

3L(114)

1S(110)

1T(115)

1W(105)

1T(115)

3T(121)

1Y(107)

2Y(109)

2W(119)

3Y(117)

2M(108)

B(114)

D(111)

V(120)

U(105)

V(120)

W(110)

B(114)

W(110)

T(115)

U(105)

T(115)

C(121)

O(107)

L(109)

M(119)

N(117)

K(108)

|