|

| |

TM 9-2320-364-20-3

2-2207

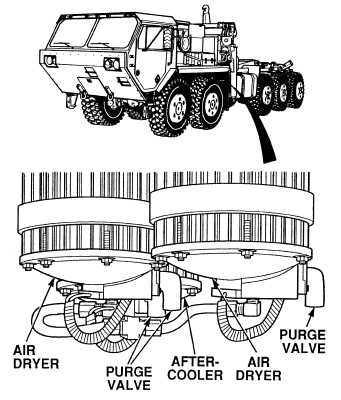

(1) Listen to air dryer while assistant

starts engine (TM 9-2320-364-10)

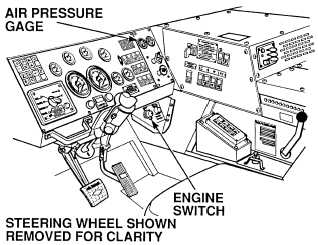

and observes AIR PRESS gages in cab

Green and red needles should move

up scale as pressure builds up.

(a) If exhaust air is heard coming from

air dryer before truck air pressure

reaches 125 4 psi (861 28 kPa),

turn OFF ENGINE switch, and

adjust or replace air governor

(Para 12-41).

(b) If exhaust air can only be heard

coming from air dryer when truck air

pressure reaches 125 4 psi

(861 28 kPa), air governor is OK.

(2) Turn OFF ENGINE switch.

(3) Install right side noise panel

(Para 17-26).

AIR GOVERNOR TEST

(1) Start engine (TM 9-2320-364-10).

(2) Run at idle for 10 minutes.

(3) Observe air pressure gage.

(a) If air pressure gage does not read

125 4 psi (861 28 kPa), fault not

corrected. Turn OFF ENGINE

switch and notify DS Maintenance.

(b) If air pressure gage reads 125 4

psi (861 28 kPa), fault has been

corrected.

(4) Turn OFF ENGINE switch.

VERIFY REPAIR

NOTE

Air will be released from air dryer when air governor

cuts out.

|