|

| |

TM 9-2320-364-20-3

2-2208

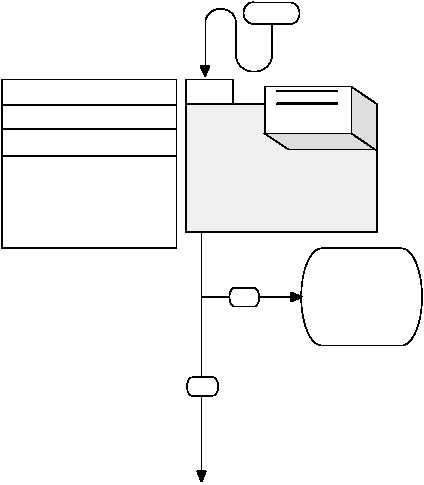

4. NOISY AIR COMPRESSOR OPERATION.

INITIAL SETUP

1.

Are oil hoses 2628 and 2630

free of damage, crimps or

leaks and are fittings free of

leaks?

START

YES

NO

Nothing.

Leaking air compressor oil

hoses.

Leaking air compressor coolant

hoses.

Air compressor or air

compressor mounting faulty

or damaged.

KNOWN INFO

POSSIBLE PROBLEMS

TEST OPTIONS

REASON FOR QUESTION

Visual inspection.

Audible inspection.

Leaking air compressor oil

hoses may cause noisy

compressor operation.

2-27. AIR SYSTEM TROUBLESHOOTING (CONT).

Tools and Special Tools

Tool Kit, General Mechanic’s: Automotive

(Item 74, Appendix G)

Equipment Condition

Engine OFF, (TM 9-2320-364-10)

Parking brakes applied, (TM 9-2320-364-10)

Wheels chocked, (TM 9-2320-364-10)

Right side noise panel removed, (Para 17-26)

References

TM 9-2320-364-10

WARNING

Tighten fittings, repair

or replace hoses 2628

and/or 2630.

Verify repair, go to

Step 4 of this Fault.

Read WARNING

on Page 2-2209

|