|

| |

TM 9-2320-364-20-5

21-168

This task covers:

a. Removal

d. Assembly

f. Adjustment

b. Disassembly

e. Installation

g. Follow-On Maintenance

c. Cleaning/Inspection

INITIAL SETUP

Equipment Condition

Engine OFF, (TM 9-2320-364-10)

Wheels chocked, (TM 9-2320-364-10)

Rail transport corner ISO locks removed,

(TM 9-2320-364-10)

Lifting frame on ground, (TM 9-2320-364-10)

Container guides removed, (TM 9-2320-364-10)

Tools and Special Tools

Tool Kit, General Mechanic’s: Automotive

(Item 74, Appendix G)

Compressor Unit, Air (Item 11, Appendix G)

Gloves, Chemical Oil Protective

(Item 28, Appendix G)

Goggles, Industrial (Item 30, Appendix G)

Gun, Air Blow (Item 31, Appendix G)

Lifting Device, Minimum Capacity

400 lbs (181 kg)

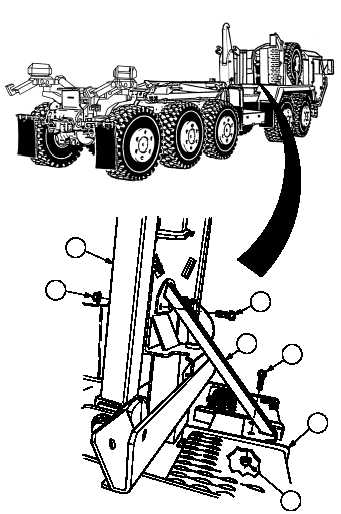

21-34. CONTAINER HANDLING UNIT (CHU) STOW WELDMENT REPLACEMENT.

Materials/Parts

Locknuts (12) (Item 91, Appendix F)

Locknuts (4) (Item 92, Appendix F)

Personnel Required

Two

a.

Removal.

Stow weldment weighs 410 lbs

(186 kg). Attach suitable lifting

device to prevent possible injury

to personnel.

(1)

Attach lifting device to stow weldment (1).

(2)

Support stow weldment (1) and remove two

screws (2) and locknuts (3)

from top of stow weldment support

brace (4). Discard locknuts.

(3)

Remove two screws (5) and locknuts (6)

from bottom of stow weldment support

brace (4) and crossmember assembly (7).

Discard locknuts.

(4)

Remove stow weldment support brace (4)

from stow weldment (1).

2

4

5

7

3

6

1

|