|

| |

TM 9-2320-364-34-2

3-156

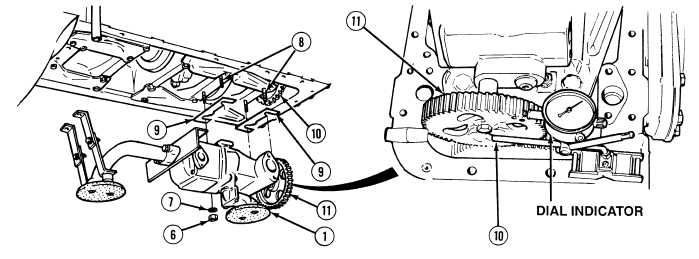

3-26. ENGINE OIL PUMP REPAIR (CONT).

e.

Installation.

(1)

With the aid of an assistant, position oil pump (1) on main bearing cap studs (8).

(2)

With the aid of an assistant, hold oil pump (1) and install four lockwashers (7) and nuts (6) on oil

pump (1) and main bearing cap studs (8).

(3)

Tighten four nuts (6) to 27 lb-ft (37 N.m).

NOTE

Backlash should be 0.006 to 0.012 in. (0.152-0.0305 mm).

(4)

Using a dial indicator, measure backlash between crankshaft gear (10) and oil pump drive gear (11).

(5)

Remove four nuts (6) and lockwashers (7) from main bearing cap studs (8). Discard lockwashers.

(6)

Remove oil pump (1) from main bearing cap studs (8).

NOTE

Each 0.005 in. shim (0.127 mm) changes gear backlash 0.0035 in. (0.0889 mm).

Add same thickness of shims on front and rear of oil pump.

(7)

Install shims (9) as necessary between oil pump (1) and main bearing cap studs (8).

(8)

Repeat Steps (1) through (3).

|