|

| |

TM 9-2320-364-34-2

9-59

(19)

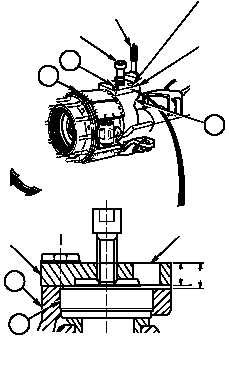

Install adjusting tool on pivot and spindle

assembly (7) with two screws (9). Tighten

screws to 200 lb-ft (271 N.m).

(20)

Install center screw in adjusting tool.

Tighten center screw to 200 lb-ft (271

N.m).

(21)

Loosen center screw slightly until wheel end

assembly (4) moves freely under its own

weight.

(22)

Center wheel end assembly (4) with pivot

and spindle assembly (7).

(23)

Tighten center screw in adjusting tool to 50

lb-ft (68 N.m).

NOTE

Measure distance through

measuring hole.

(24)

Using a depth gage, measure distance from

top of adjusting tool to top of pivot and

spindle assembly (7) and record as

dimension A.

(25)

Using a depth gage, measure distance from top of adjusting tool to top of trunnion (12) and record as

dimension B.

(26)

Subtract dimension A from dimension B (B - A). The answer is the gap between pivot and spindle

assembly (7) and top of trunnion (12).

(27)

Refer to Table 9-2 to determine shim thickness.

(28)

Remove screws (9) and adjusting tool and rotate wheel end assembly (4) to centered position.

Table 9-2. Determining Shim Thickness

Gap between pivot and spindle

assembly and trunnion

Shim thickness

0.018 to 0.022 in. (0.46 - 0.56 mm)

0.016 in. (0.4 mm)

0.022 to 0.026 in. (0.56 - 0.66 mm)

0.020 in. (0.5 mm)

0.026 to 0.030 in. (0.66 - 0.76 mm)

0.024 in. (0.6 mm)

0.030 to 0.033 in. (0.76 - 0.84 mm)

0.028 in. (0.7 mm)

0.033 to 0.037 in. (0.84 - 0.94 mm)

0.031 in. (0.8 mm)

0.037 to 0.041 in. (0.94 - 1.04 mm)

0.035 in. (0.9 mm)

0.041 to 0.045 in. (1.04 - 1.14 mm)

0.039 in. (1.0 mm)

4

B

MEASURING HOLE

ADJUSTING

TOOL

MEASURING

HOLE

DEPTH

GAGE

CENTER SCREW

ADJUSTING

TOOL

ROTATE

A

12

7

9

7

|