|

| |

TM 9-2320-364-34-2

9-100

9-13. AXLE NO. 5 ASSEMBLY REPLACEMENT

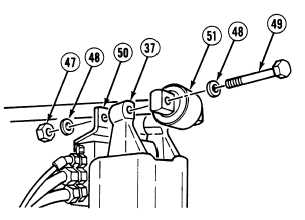

(8)

Install axle end of torque rod (51) and air

manifold bracket (50) on Axle No. 5 (37)

with two screws (49), four washers (48) and

two locknuts (47).

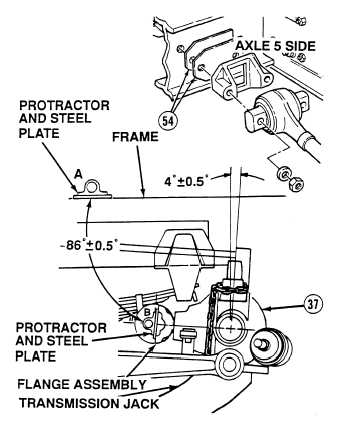

NOTE

Equalizer beams and frame must be level to perform axle camber adjustment properly.

Axle camber angle measurements must be taken with relationship to frame. If frame is not

level, the angle the frame is inclined must be added or subtracted from flange assembly

measurement.

Axle flange measurement of 86 0.5 degrees equals axle camber of four degrees 0.5 (90

degrees – 86 degrees = 4 degrees).

(9)

Position protractor and steel plate on frame

at point A. Adjust protractor to zero.

(10)

Position protractor and steel plate on

machined surface of the flange assembly

and record measurement. This is point B.

Measurement should read 86 degrees 0.5

degrees.

(11)

Subtract measurement recorded at point B

from 90 degrees. This will be axle camber.

Axle No. 4 and Axle No. 5 share

mounting hardware for

longitudinal torque rods. Both

axles must be supported during

removal of screws and locknuts

or axles may fall. Failure to

comply may result in injury or

death to personnel.

(12)

If Axle No. 5 camber is not four degrees

0.5 degrees, support Axle No. 4 and add or

subtract spacers (54) until correct axle

camber is achieved.

(13)

Remove transmission jack from

Axle No. 5 (37).

|