|

| |

TM 9-2320-364-34-3

14-40

Materials/Parts

Grease (Item 21, Appendix B)

Oil, Lubricating (Item 37, Appendix B)

This task covers:

a. Axle No. 1 Lateral Torque Rod Replacement

d. Axle No. 4 Lateral Torque Rod Replacement

b Axle No. 2 Lateral Torque Rod Replacement

e. Axle No. 5 Lateral Torque Rod Replacement

c. Axle No. 3 Lateral Torque Rod Replacement

f. Follow-On Maintenance

INITIAL SETUP

Personnel Required

Two

Equipment Condition

Engine OFF, (TM 9-2320-364-10)

Wheels chocked, (TM 9-2320-364-10)

LHS fully extended, (TM 9-2320-364-10)

(Axles No. 3 and No. 4 only)

Rear hardlift assembly removed,

(TM 9-2320-364-20) (Axle No. 5 only)

Tools and Special Tools

Tool Kit, General Mechanic’s

(Item 240, Appendix F)

Hammer, Hand, Soft Plastic,

(Item 88, Appendix F)

Jack, Kit, Hydraulic, Hand

(Item 129, Appendix F)

Wrench Set, Socket 3/4 in. Drive

(Item 274, Appendix F)

Wrench, Torque (0-600 lb-ft [0-814 N.m])

(Item 278, Appendix F)

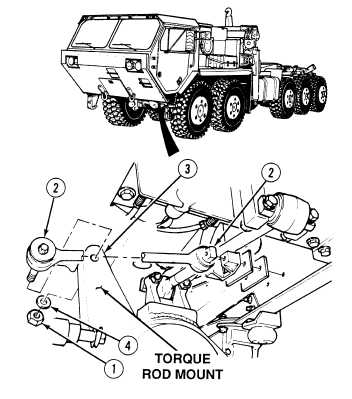

14-8. LATERAL TORQUE ROD REPLACEMENT.

Materials/Parts - Continued

Tags, Identification (Item 72, Appendix B)

Locknut (10) (Item 166, Appendix E)

Locknut (5) (Item 181, Appendix E)

Locknut (2) (Item 192, Appendix E)

a.

Axle No. 1 Lateral Torque Rod Replacement.

(1)

Removal.

(a)

Loosen locknut (1) until locknut is

even with threaded end of torque

rod (2).

Torque rod is under extreme

pressure when being pressed

from axle. Torque rod can be

dangerous when it breaks loose

and could cause injury to

personnel.

(b)

With the aid of an assistant and use of a

hand jack kit, press tapered end of

torque rod (2) from axle (3) while

striking torque rod mount with soft

faced hammer.

(c)

Remove locknut (1) and washer (4)

from torque rod (2). Discard locknut.

|