|

| |

TM 9-2320-364-34-3

16-84

Materials/Parts

Sealing Compound (Item 56, Appendix B)

Tags, Identification (Item 72, Appendix B)

This task covers:

a. Removal

b. Installation

c. Follow-On Maintenance

INITIAL SETUP

Personnel Required

Two

Equipment Condition

Engine OFF, (TM 9-2320-364-10)

Wheels chocked, (TM 9-2320-364-10)

Hoist cable removed, (TM 9-2320-364-20)

Hoist motor valve removed, (Para 16-13)

Tools and Special Tools

Tool Kit, General Mechanic’s

(Item 240, Appendix F)

Wrench, Combination 1 1/2 in.

(Item 260, Appendix F)

Wrench Set, Socket 3/8 in. Drive

(Item 273, Appendix F)

Wrench Set, Socket 3/4 in. Drive

(Item 274, Appendix F)

Wrench, Torque (0-60 N.m)

(Item 276, Appendix F)

Lifting Device, Minimum Capacity 250 lbs

(114 kg)

16-11. HOIST ASSEMBLY REPLACEMENT.

Materials/Parts - Continued

Lockwasher (Item 282, Appendix E)

Lockwasher (2) (Item 283, Appendix E)

Packing, Preformed (2) (Item 348, Appendix E)

Packing, Preformed (Item 372, Appendix E)

a.

Removal.

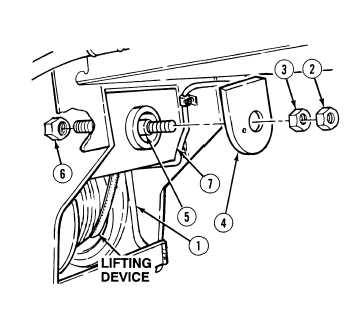

Hoist assembly weighs 210 lbs

(95 kg). Attach suitable lifting

device prior to removal to

prevent possible injury to

personnel.

(1)

Wrap and attach lifting device around

assembly (1).

To avoid damage to tension

load cell cable, do not allow

tension load cell to turn

when removing nuts.

Count exposed threads on tension load cell before nuts are removed to ensure nuts are

reinstalled to same positions.

(2)

Remove jam nut (2), swivel nut (3) and end cap (4) from tension load cell (5).

(3)

Remove swivel nut (6) from front of tension load cell (5) at hoist mount (7).

|