|

| |

TM 9-2320-364-34-4

28-73

Materials/Parts

Oil, Hydraulic (Item 34, Appendix B)

Solvent, Drycleaning (Item 68, Appendix B)

Lockwasher (6) (Item 232, Appendix E)

Repair Kit (Item 462, Appendix E)

Repair Kit (Item 463, Appendix E)

This task covers:

a. Removal

c. Cleaning/Inspection

e. Installation

b. Disassembly

d. Assembly

f. Follow-On Maintenance

INITIAL SETUP

Equipment Condition

Hydraulic motor removed, (Para 28-12)

Tools and Special Tools

Tool Kit, General Mechanic’s

(Item 240, Appendix F)

Compressor Unit, Air (Item 35, Appendix F)

Gloves, Chemical Oil Protective

(Item 81, Appendix F)

Goggles, Industrial (Item 83, Appendix F)

Gun, Airblow (Item 86, Appendix F)

Hammer, Hand Soft Plastic

(Item 88, Appendix F)

Micrometer, Outside, Caliper, Set

(Item 139, Appendix F)

Wrench, Torque (0-175 lb-ft [0-237 N.m])

(Item 277, Appendix F)

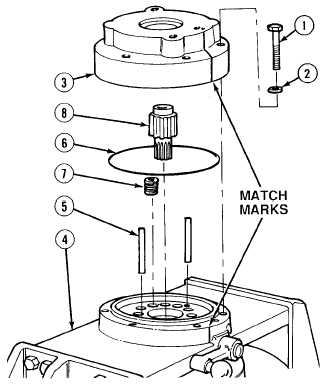

28-13. SELF-RECOVERY WINCH BRAKE REPAIR.

Tools and Special Tools - Continued

Wooden Block (2) (Appendix C)

a.

Removal.

(1)

Remove six screws (1) and lockwashers (2)

from brake housing (3). Discard

lockwashers.

NOTE

Twelve springs may fall out

upon removal of brake housing.

Dowel pins may or may not

come out with removal of

brake housing.

Matchmark position of brake

housing and front motor

support prior to removal.

(2)

Remove brake housing (3) from front motor

support (4).

(3)

Remove dowel pins (5) from brake

housing (3) or front motor support (4).

(4)

Remove and discard preformed packing (6)

from front motor support (4).

(5)

Remove twelve springs (7) from front motor

support (4). Discard springs.

(6)

Remove brake shaft (8) from front motor

support (4).

|