|

| |

TM 9-2320-364-34-4

20-190

20-61. CYLINDER LINER REPAIR (CONT).

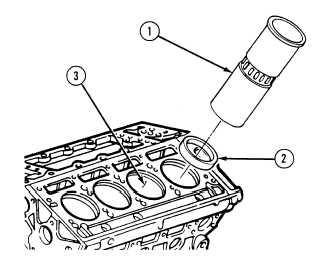

Do not drop cylinder liner into

cylinder bore. Damage to

cylinder liner will result.

NOTE

Cylinder liners must be

installed in their original

bores.

Cylinder liner is installed

when liner flange rests on

insert.

(8)

Install cylinder liners (1) and inserts (2) in

cylinder bore (3).

b.

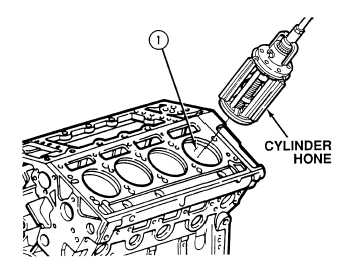

Honing.

Do not hone new cylinder liner.

New liners are factory finished

and honing could affect seating

of piston rings. Hone the liner if

glazed, ridged, out of round, or

tapered.

(1)

Coat inside of cylinder liner (1) with

honing oil.

(2)

Install hone with 120 grit stones, into

cylinder liner (1).

(3)

Work hone up and down in cylinder liner (1)

at 300 to 400 rpm. Move hone full length of

cylinder liner (1) so hone produces marks in

crisscross pattern at a 45 degrees angle.

(4)

Remove hone after glaze has been removed

from cylinder liner (1).

|