|

| |

TM 9-2320-364-34-4

20-201

Protect machined surfaces of

camshaft from damage due to

contact with V blocks by folding

rags over V block.

(10)

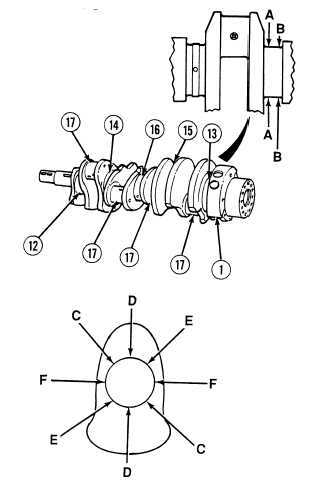

Support crankshaft on two machined V blocks

at the front main journal (12) and rear main

journal (13).

NOTE

Maximum runout for journals 2

and 4 is 0.002 in. (0.051 mm).

Maximum runout for main bearing

journal 4 is 0.004 in. (0.102 mm).

Difference between runout measure-

ments for two adjacent journals must

not exceed 0.003 in. (0.076 mm).

When runout high spots of adjacent

journals are at right angles to each

other, sum of their runout measure-

ments must not exceed 0.004 in.

(0.102 mm).

Replace crankshaft if runout is not

within specifications.

(11)

Using dial indicator, measure crankshaft runout at journals (14), (15), and (16). Rotate crankshaft one

complete turn. Record readings and note locations of runout high spots on journals.

(12)

Install two more machined V-blocks under two journals to support crankshaft.

NOTE

If any crankshaft journal is not within specification, replace crankshaft.

(13)

Using a micrometer, measure crankshaft journals. At point A measure around shaft at points C through F.

At point B measure around the shaft at points C through F. Compare measurements with the following

limits.

(a)

Diameter of main bearing journals (12), (13), (14), (15) and (16) must be minimum of 4.4985 in.

(11.4262 cm) and maximum of 4.5002 in. (11.4305 cm).

(b)

Connecting rod journals (17) diameter must be minimum of 2.9985 in. (7.616 cm) and maximum of

3.0002 in. (7.6205 cm).

(c)

Check main bearing journals (12), (13), (14), (15) and (16) and connecting rod journals (17) for

out-of-round. Journal out-of-round must not exceed 0.0005 in. (0.0127 mm).

(d)

Check main bearing journals (12), (13), (14), (15) and (16) for taper. Taper must not exceed 0.004

in. (0.102 mm).

(e)

Check connecting rod journals (17) for taper. Taper must not exceed 0.004 in. (0.102 mm) (half

width) and 0.008 in. (0.203 mm) (full width).

|