|

| |

TM 9-2320-364-34-4

23-39

b.

Disassembly.

(1)

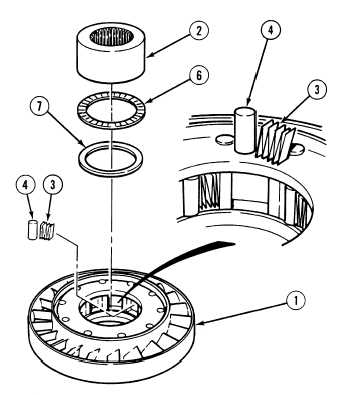

Position stator assembly (1) rear side up.

NOTE

Roller race is removed by

rotating clockwise and pulling

upward.

(2)

Remove roller race (2) from stator

assembly (1).

(3)

Note position of springs (3) and remove ten

rollers (4) and ten springs (3) from stator

assembly (1).

(4)

(4) Remove thrust bearing (6) and thrust

bearing race (7) from stator assembly (1).

(5)

Wrap thrust bearing (6) and thrust bearing

race (7) in clean lint-free cloth or paper until

ready to clean and inspect.

c.

Cleaning/Inspection.

Drycleaning Solvent (P-D-680) is TOXIC and flammable. Wear protective goggles, face

shield, and gloves; use only in a well-ventilated area; avoid contact with skin, eyes, and

clothes, and do not breathe vapors. Keep away from heat or flame. Never smoke when

using solvent. The flashpoint for Type II Drycleaning Solvent is 140 degrees F (60 degrees

C) and Type III Drycleaning Solvent is 200 degrees F (93 degrees C). Failure to do so may

result in injury or death to personnel.

If personnel become dizzy while using cleaning solvent, immediately get fresh air and

medical help. If solvent contacts skin or clothes, flush with cold water. If solvent contacts

eyes, immediately flush eyes with water and get immediate medical attention.

Keep bearings clean. The presence of dirt or grit on bearing rollers/balls is usually responsible

for bearing failures. It is important to keep bearings clean during Removal, Inspection, and

Installation. To make sure maximum bearing life, do not remove wrapper from new or clean

used bearings until ready to install them. Do not remove grease in which bearings are packed.

Do not lay bearings on a dirty bench; place them on a clean lint-free paper. If assembly is not

to be completed at once, wrap or cover the exposed bearings with clean paper or lint-free cloth

to keep out dust.

(1)

Clean all parts with drycleaning solvent.

|