|

| |

TM 9-2320-364-34-4

23-40

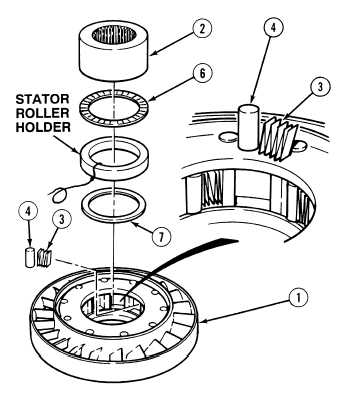

23-10. TORQUE CONVERTER STATOR REPAIR (CONT).

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use only with

effective chip guarding and personal protective equipment (goggles/shield, gloves, etc).

Failure to comply may result in injury or death to personnel.

(2)

Dry parts, except bearing, with compressed air. Allow bearings to air dry.

(3)

Lubricate bearing with hydraulic oil.

(4)

Inspect bearings for roughness of rotation. Replace bearing if rotation is still rough after cleaning and

oiling.

d.

Assembly.

(1)

Install thrust bearing race (7) in rear side of

stator assembly (1).

(2)

Coat pockets of stator assembly (1), springs

(3) and rollers (4) with petrolatum.

NOTE

Make sure cord of roller holder

hangs out bottom of stator.

(3)

Install stator roller holder in stator

assembly (1) against thrust bearing race (7).

(4)

Install ten springs (3) in stator assembly (1).

Springs must be positioned as shown.

(5)

Install ten rollers (4) in stator assembly (1).

(6)

Install thrust bearing (6) onto roller race (2).

NOTE

Rotate roller race clockwise to

properly install in stator

assembly.

(7)

Install roller race (2) into stator

assembly (1).

(8)

Remove stator roller holder by pulling on

attached cord. Push roller race (2) in,

rotating it clockwise, until thrust bearing (6)

seats.

(9)

Rotate roller race (2) counterclockwise to lock in place. Position stator assembly (1) with roller race up.

|