|

| |

TM 9-2320-364-34-4

23-82

23-14. FIFTH CLUTCH REPAIR (CONT).

(6)

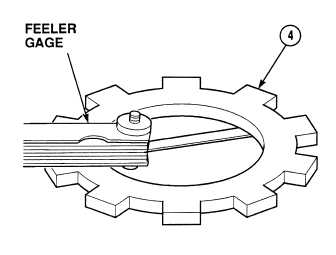

Inspect external-tanged plates (4) for

scoring, excessive wear, cone distortion,

imbedded metal, galling, cracks, breaks, and

damaged or missing tangs. Remove burrs

and minor surface irregularities, using soft

honing stone. Replace defective plates.

(7)

Measure clearance between inside diameter

of each external-tanged plate (4) and level

surface to determine cone. Discard plates

having clearance in excess of 0.010 in.

(0.254 mm).

(8)

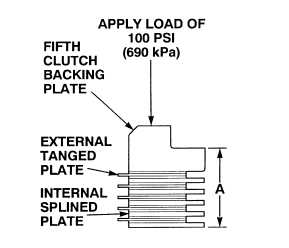

Stack fifth clutch plates and backplate in

press as shown.

(9)

Evenly apply specified load. Measure

dimension A.

(10)

Select proper fifth clutch piston from

Table 23-2.

(11)

Tie parts together and tag.

Table 23-2. Fifth Clutch Piston

If Piston

Is Marked

Dimension A

Should Be

X

1.3615 - 1.3878 in.

(34.582 - 35.250 mm)

Y

1.3882 - 1.4148 in.

(35.260 - 35.935 mm)

Z

1.4152 - 1.4415 in.

(35.946 - 36.614 mm)

|