|

| |

TM 9-2320-364-34-4

25-70

25-15. AXLE NO. 1 AND 5 DIFFERENTIAL ASSEMBLY REPAIR (CONT).

(17)

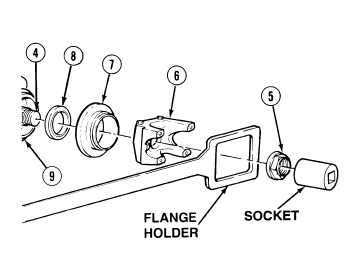

Coat oil seal (8) with grease.

(18)

Install oil seal (8) in axle housing (9).

(19)

Install dust cover (7) on flange assembly (6).

NOTE

Flange assembly should be positioned so large openings of flange assembly align with slots

of pinion shaft. This will ease staking of nut.

(20)

Position flange assembly (6) on pinion shaft (4).

Adhesives, solvents, and sealing compounds can burn easily, can give off harmful vapors, and

are harmful to skin and clothing. To avoid injury or death, keep away from open fire and use

in a well-ventilated area. If adhesive, solvent, or sealing compound gets on skin or clothing,

wash immediately with soap and water.

(21)

Coat threads of pinion shaft (4) with

adhesive.

(22)

Apply adhesive to face of flange assembly

(6) where adjusting nut (5) seats.

(23)

With the aid of an assistant and using flange

holder and socket, install adjusting nut (5)

on pinion shaft (4). Tighten adjusting nut to

486 to 572 lb-ft (659 to 776 N.m).

(24)

Ensure adhesive has squeezed out around

entire outside diameter of adjusting nut (5).

If adhesive is not visible around entire

outside diameter of adjusting nut (5),

remove and discard adjusting nut (5) and

repeat Steps (21) through (23).

|