|

| |

TM 9-2320-364-34-4

25-82

25-16. AXLE NO. 2 DIFFERENTIAL ASSEMBLY REPAIR (CONT).

b.

Disassembly.

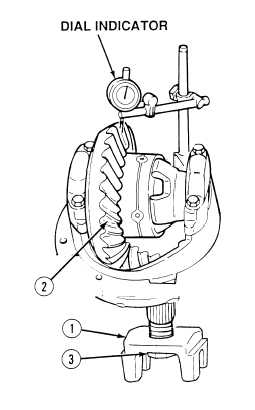

Make sure pinion shaft does not

move while backlash is being

measured or incorrect reading

will result.

(1)

With the aid of an assistant, hold yoke (1)

while turning differential gear (2) counter

clockwise until gear stops to take up

backlash.

NOTE

Shaft from dial indicator must be

at right 90 degree angle to face of

tooth when in contact.

(2)

Install dial indicator on face of differential

gear tooth (2).

(3)

Turn differential gear (2) clockwise until

gear stops.

NOTE

Record differential gear to

pinion shaft backlash and

contact pattern. Backlash

should be 0.010 to 0.016 in.

(0.254 to 0.406 mm).

(4)

Check differential gear (2) to pinion

shaft (3) backlash measured on dial indicator

and contact pattern.

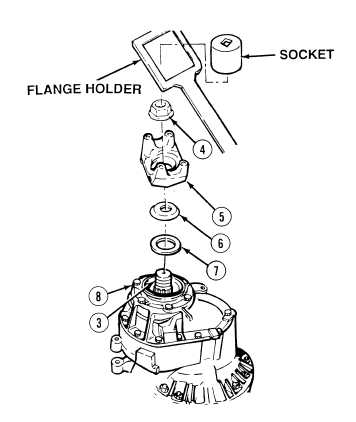

(5)

Unstake adjusting nut (4) on pinion

shaft (3).

(6)

With the aid of an assistant and using flange

holder and socket, remove adjusting nut (4)

from pinion shaft (3). Discard adjusting nut.

(7)

Remove flange assembly (5) from pinion

shaft (3).

(8)

Separate dust cover (6) from flange

assembly (5).

(9)

Using puller, remove seal (7) from

differential assembly (8). Discard oil seal.

|