|

| |

TM 9-2320-364-34-4

25-127

Adhesives, solvents and sealing

compounds can burn easily, can

give off harmful vapors and are

harmful to skin and clothing. To

avoid injury or death, keep away

from open fire and use in well-

ventilated area. If adhesive,

solvent, or sealing compound

gets on skin or clothing, wash

immediately with soap and

water.

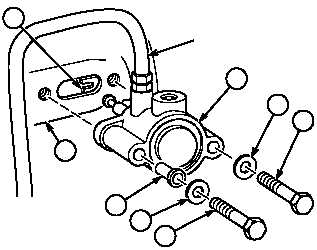

(9)

Coat mating surface of differential (8) with

adhesive.

(10)

Position locking cylinder (4) on

differential (8).

(11)

Install plastic washer (7), washer (6) and

screw (5) in locking cylinder (4).

NOTE

Install screw so that only three

or four threads of screw are

engaged. Screw is being

installed only to keep screw hole

in locking cylinder aligned with

differential.

(12)

Position washer (2) and screw (1) in locking

cylinder (4).

(13)

Tighten screw (1) in locking cylinder (4) to

25 to 32 lb-ft (34 to 43 N.m).

(14)

Connect air supply test air hose to locking

cylinder (4).

(15)

Using air supply shop air hose, apply air

pressure 100 to 120 psi (690 to 827 kPa) to

locking cylinder (4).

(16)

Turn flange assemblies back and forth until

locking cylinder (4) engages.

(17)

Turn screw (1) slowly until screw contacts

fork (15) in differential (8).

(18)

Using dial caliper, measure distance between

face of washer (2) and top of locking

cylinder (4) and record as measurement “A”.

4

2

1

5

8

6

7

15

AIR SUPPLY HOSE

|