|

| |

TM 9-2320-364-34-4

25-131

(6)

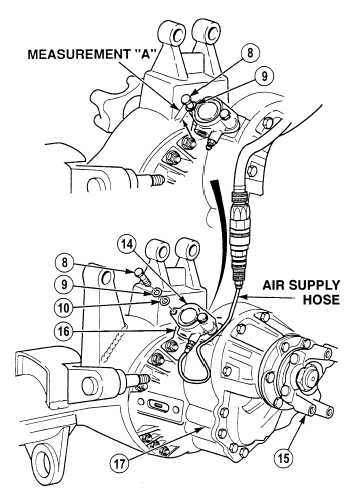

Connect air supply hose to locking

cylinder (14).

(7)

Using air supply hose, apply air pressure

100 to 120 psi (690 to 827 kPa) to locking

cylinder (14).

NOTE

When locking cylinder engages

both input shaft and output shaft

ends will turn in the same

direction, while turning input

shaft.

(8)

Turn front flange assembly (15) back and

forth until locking cylinder (14) engages.

(9)

Turn screw (8) slowly until screw contacts

fork (16) in differential (17).

(10)

Using dial caliper, measure distance from

face of washer (9) to top of locking

cylinder (14) and record and

measurement “A”.

(11)

Determine shim (10) thickness. Shim

thickness is measurement A – 0.004 to

0.020 in. (0.102 to 0.508 mm).

(12)

Remove screw (8) and washer (9).

NOTE

Shim thickness is determined in

Step (11).

(13)

Install shim (10), washer (9) and screw (8)

on locking cylinder (14). Tighten screw to

25 to 32 lb-ft (34 to 43 N.m).

(14)

Remove air supply hose from locking

cylinder (14).

|