|

| |

TM 9-2320-364-34-4

25-180

25-28. AXLE NO. 3 DIFFERENTIAL ASSEMBLY REPAIR (CONT).

Adhesives, solvents and sealing

compounds can burn easily, can

give off harmful vapors and are

harmful to skin and clothing. To

avoid injury or death, keep away

from open fire and use in a well-

ventilated area. If adhesive,

solvent, or sealing compound

gets on skin or clothing, wash

immediately with soap and

water.

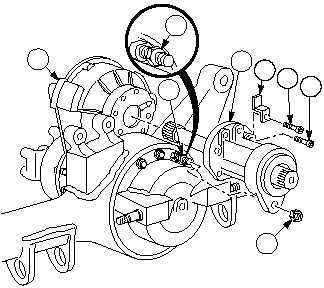

(25)

Coat mating surfaces of rear output

assembly (2) and differential housing (6)

with adhesive.

(26)

Coat threads of six screws (3) and screw (4)

with sealing compound.

(27)

Install rear output assembly (2) on

differential assembly (6) with six screws (3).

Tighten screws to 61 to 80 lb-ft (83 to 108

N.m).

(28)

Install screw (4) and bracket (5) on rear

output assembly (2). Tighten screw to 61 to

80 lb-ft (83 to 108 N.m).

(29)

Turn nut (10) until it contacts rear output

assembly (2).

(30)

Install nut (1). Tighten nut to 128 to 150

lb-ft (174 to 203 N.m).

(31)

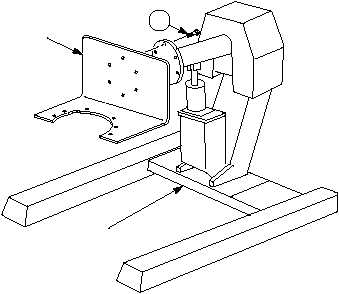

With the aid of an assistant, remove six

screws (17) and differential adapter from

engine stand.

f.

Follow-On Maintenance:

Install Axle No. 3 rear flange assembly, (Para 25-26).

END OF TASK

17

DIFFERENTIAL

ADAPTER

ENGINE

MAINTENANCE

STAND

2

5

4

3

6

1

10

10

|