|

|||

|

|

|||

|

Page Title:

BLACKOUT STOPLIGHT(S) DO NOT OPERATE. |

|

||

| ||||||||||

|

|

TM 9-2330-385-14

4-13. 24 VOLT ELECTRICAL SYSTEM TROUBLESHOOTING PROCEDURES (CONT).

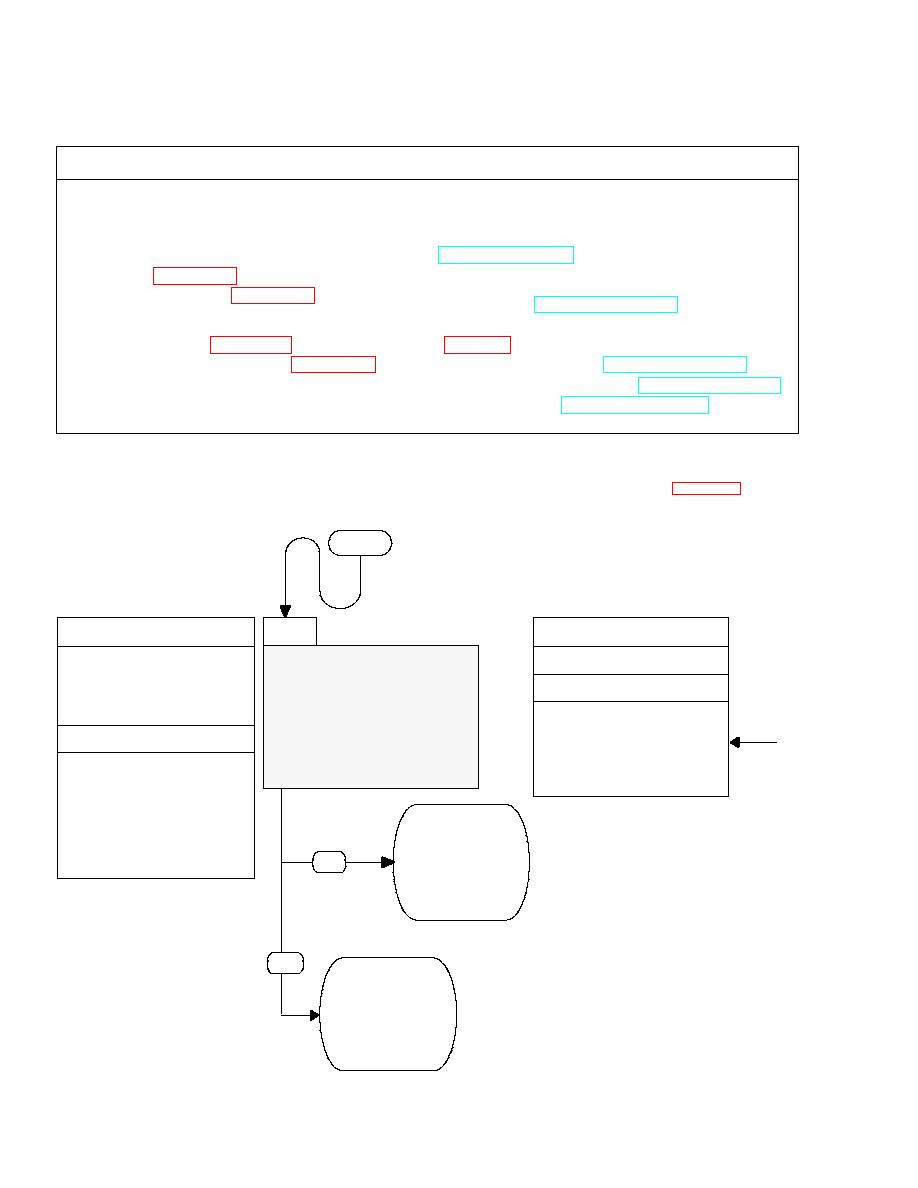

7. BLACKOUT STOPLIGHT(S) DO NOT OPERATE.

INITIAL SETUP

Tools and Special Tools

References

Tool Kit, General Mechanic's: Automotive

TM 9-2320-364-10

(Item 50, Appendix J)

Equipment Condition

Multimeter (Item 28, Appendix J)

Engine OFF, (TM 9-2320-364-10)

24 vdc cable assembly connected to truck,

Materials/Parts

Locknut (Item 31, Appendix I)

Packing, Preformed (Item 59, Appendix I)

Parking brake applied, (TM 9-2320-364-10)

Truck air pressure charged, (TM 9-2320-364-10)

Personnel Required

Wheels chocked, (TM 9-2320-364-10)

Two

NOTE

The following troubleshooting procedures cover the left blackout stoplight, but they apply to both blackout stoplights.

D

All electrical wires and components listed in this troubleshooting procedure are illustrated and located in Figure FO-1.

D

Trailer may be equipped with composite lights or LED composite lights

D

START

1.

KNOWN INFO

TEST OPTIONS

Truck electrical system OK.

Visual inspection.

Does at least one blackout

All other trailer lights operate.

stoplight operate when

Taillights operate indicating

REASON FOR QUESTION

brakes are applied?

LED composite light ground

If no blackout stoplights operate,

is OK

fault is 24 vdc cable assembly

POSSIBLE PROBLEMS

through wire 1678C-18. If at

least one stoplight operates,

Blackout stoplight faulty.

fault is rear junction box through

Blackout stoplight lamp faulty.

composite light.

Wire 1678/23-28 faulty.

24 vdc cable faulty.

Connector MC15 faulty.

Front junction box faulty.

Wire 1678C-18 faulty.

Go to Step 6 of this

Rear junction box faulty.

NO

Fault.

YES

If composite lights

are installed, go to

Step 2 of this Fault.

If LED composite

lights are installed, go

to Step 5 of this Fault.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |