|

|||

|

|

|||

|

Page Title:

EXCESSIVE BRAKING DISTANCE (CONT). |

|

||

| ||||||||||

|

|

TM 9-2330-385-14

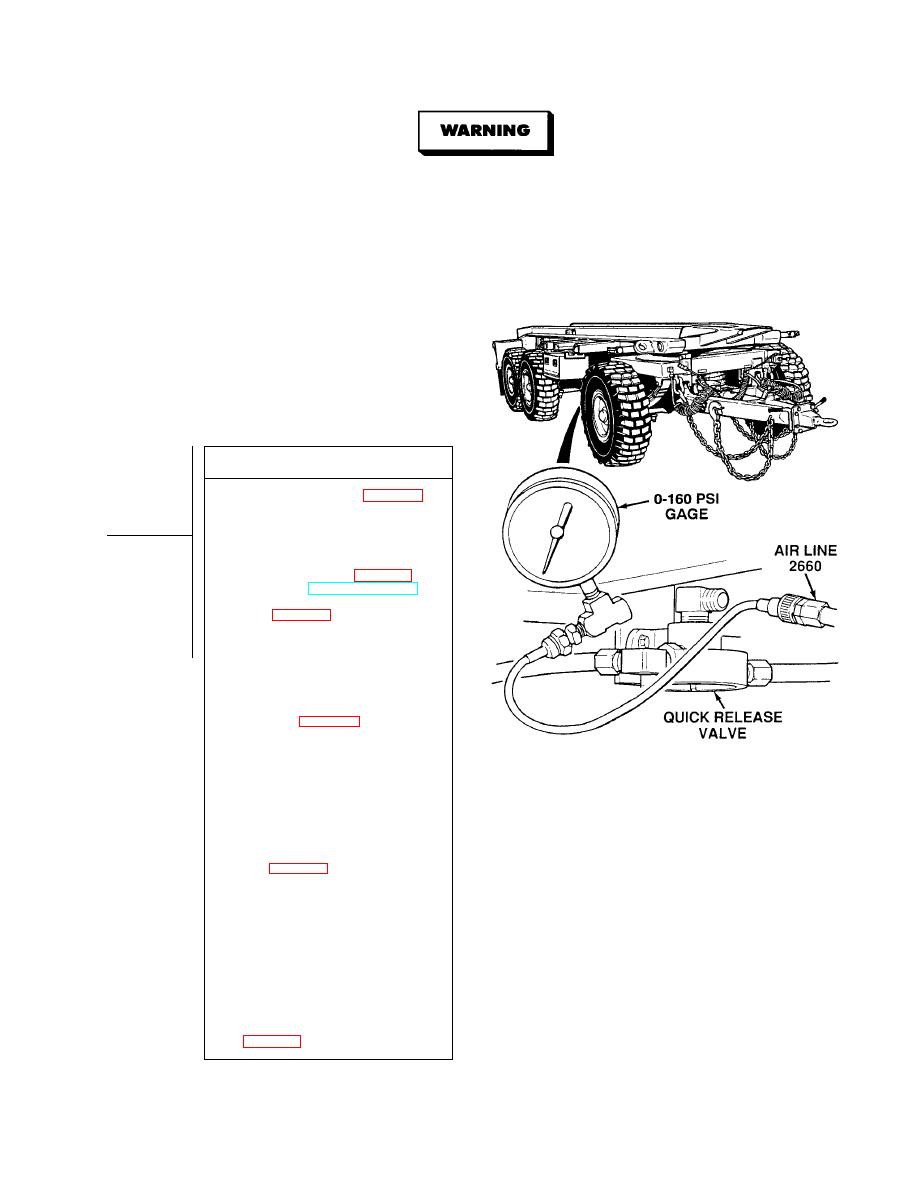

If air lines are disconnected when they are under 125 5 psi (862 34 kPa), they can whip around and

cause personal injury. Care should be exercised when disconnecting an air hose that is thought to be

under pressure.

NOTE

When rod is disconnected from the valve it

should hang freely without interference from

other components. During testing of load

sensing valve, control rod must be able to

simulate a no load condition.

PRESSURE TEST

(1) Drain trailer air system (Para 2-21).

(2) Disconnect air hose 2660 from quick

release valve.

(3) Connect 0-160 psi (1103 kPa)

pressure gage to air hose 2660.

(4) Disconnect load sensing valve

control rod from axle (Para 4-53).

(5) Start engine (TM 9-2320-364-10).

(6) Push in trailer charge valve in

truck (Para 2-22).

(7) While assistant fully applies brake

pedal, push up on control rod and

observe pressure gage.

(a) If valve output pressure does

not go to 120 5 psi

(827 34 kPa), perform Steps (9)

through (14) below and replace

valve (Para 4-53).

(b) If valve output pressure does

go to 120 5 psi (827 34 kPa),

go to Step (8) below.

(8) While assistant fully applies brake

pedal, pull down on control rod and

observe pressure gage.

(a) If valve output pressure is less

than 30 5 psi (207 34 kPa),

perform Steps (9) through (14)

below and replace valve

(b) If valve output pressure does go

to 30 5 psi (207 34 kPa),

valve is OK.

(9) Release brake pedal.

(10) Pull out trailer charge valve in truck.

(11) Turn OFF ENGINE switch.

(12) Disconnect air hose 2660 from

pressure gage.

(13) Connect air hose 2660 to quick

release valve.

(14) Connect control rod to axle.

(15) Adjust load sensing valve

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |