|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2330-385-14

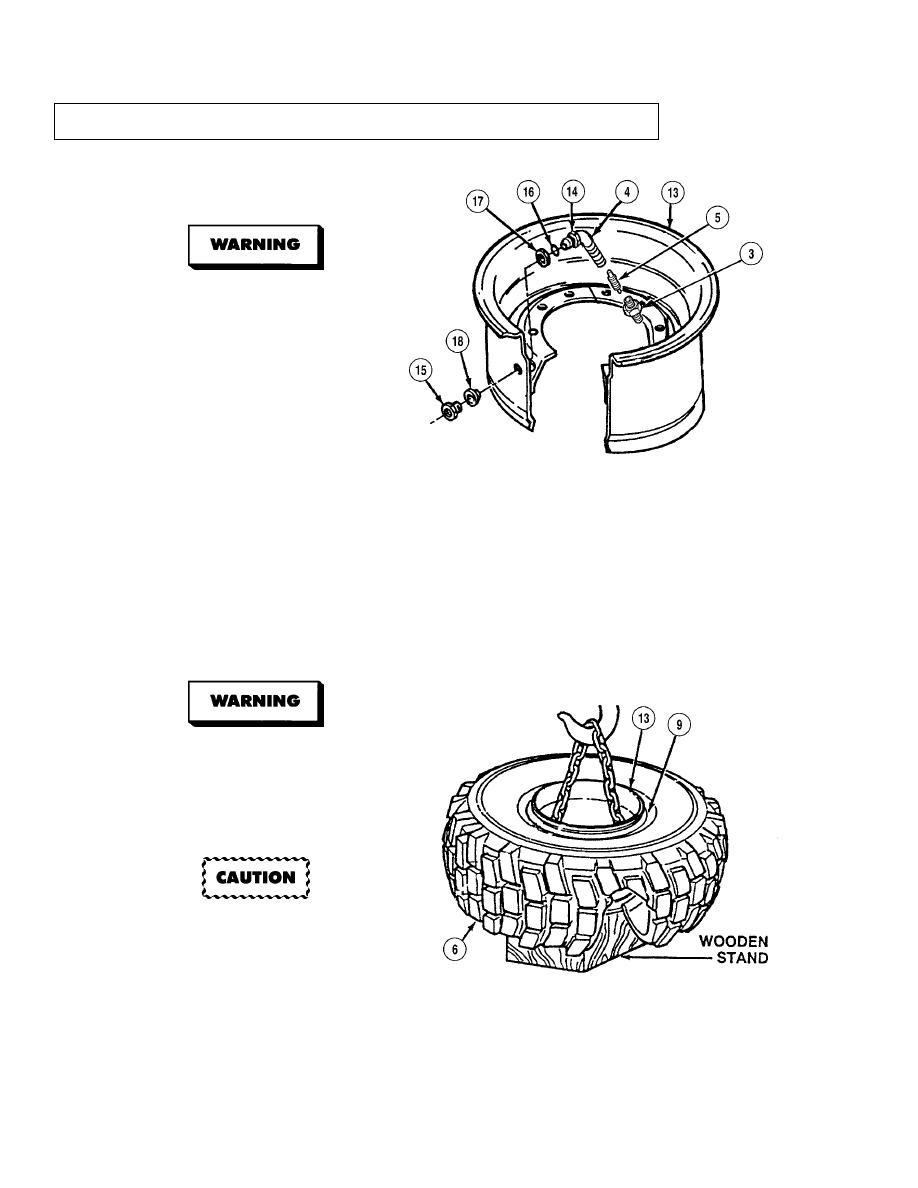

4-56. WHEEL/TIRE ASSEMBLY REPAIR (THREE-PIECE WHEEL) (CONT).

c.

Assembly.

(1)

Install grommet (18) on rim spud (15).

Adhesives, solvents, and sealing

compounds can burn easily, can

give off harmful vapors and are

harmful to skin and clothing. To

avoid injury or death, keep away

from open fire and use in a well-

ventilated area. If adhesive,

solvent, or sealing compound

gets on skin or clothing, wash

immediately with soap and

water.

(2)

Apply sealing compound to first two threads of rim spud (15).

Install rim spud (15) in wheel (13) with nut (17). Tighten nut to 15 to 17 lb-ft (20 to 23 N.m).

(3)

(4)

Coat preformed packing (16) with tire lubricant.

(5)

Install preformed packing (16) on stem (4).

(6)

Apply sealing compound to first two threads of nut (14).

Install stem (4) into rim spud (15) and tighten nut (14) to 70 to 80 lb-in (8 to 9 N.m).

(7)

(8)

Install valve core (5) into stem (4).

(9)

Install adapter (3) on stem (4).

Wheel weighs 110 lbs (50 kg).

Use suitable lifting device to lift

wheel assembly and prevent

possible injury to personnel.

(10) Using a lifting device, position wheel (13) on

wooden stand with flange side facing down.

Never use silicone, solvents, or

petroleum based lubricants on

tire bead or tire bead seat areas.

Failure to comply may result in

damage to equipment.

(11) Lubricate tire bead (9) and bead seat areas of

wheel (13) with tire lubricant, making sure

excess lubricant does not run down into tire (6).

(12)

Position tire (6) on wheel (13).

4-512

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |