|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2330-385-14

NOTE

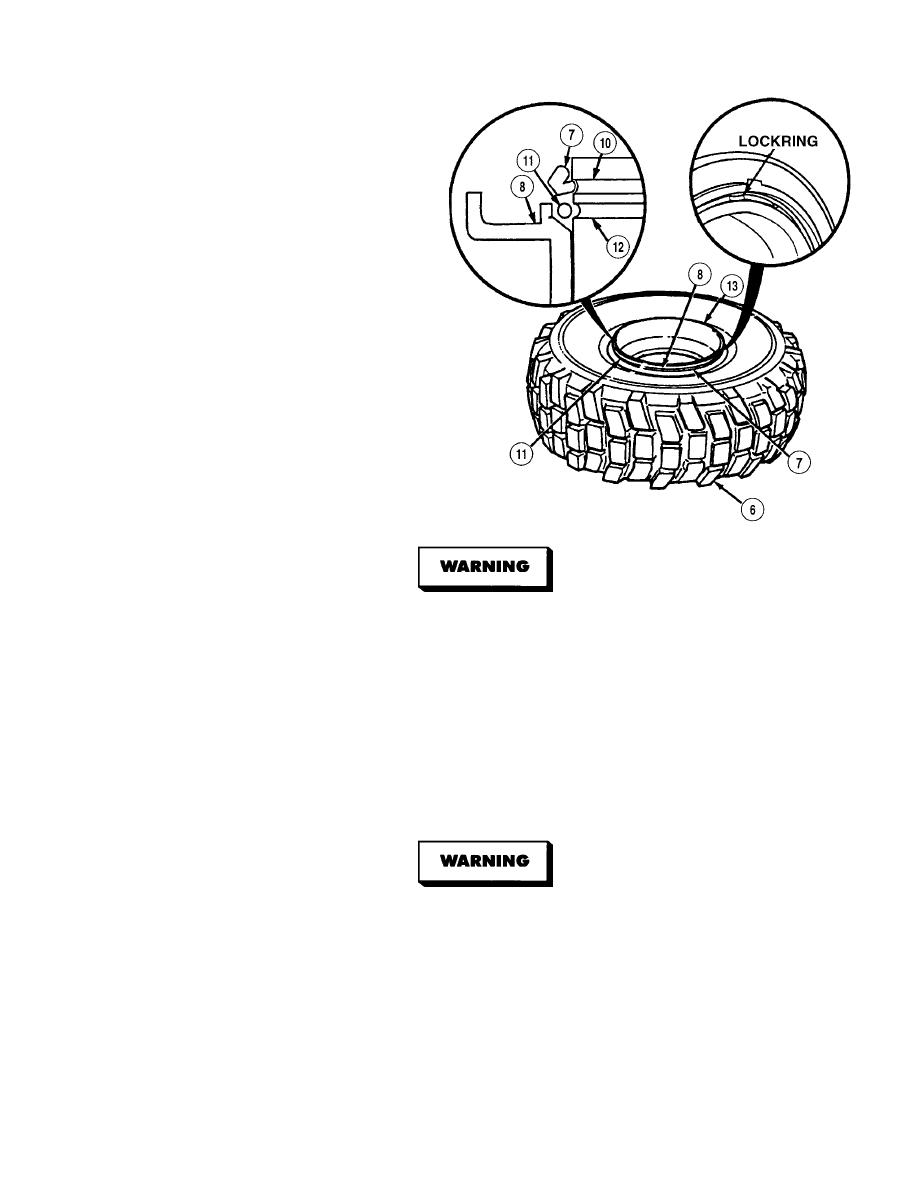

Standing on side ring may aid in

assembly.

(13)

Lubricate and position side ring (8) on

wheel (13) and tire (6) and push straight

down, ensuring side ring (8) does not

bind on wheel (13).

(14)

Lubricate preformed packing (11) with tire

lubricant.

NOTE

It may be necessary to hold down

side ring with flat end of tire tool

to expose preformed packing

groove.

(15)

Install preformed packing (11) in

preformed packing groove (12).

When lock ring snaps into position it could pinch hands and fingers. Do not allow hands or

fingers to get between lock ring and lock ring groove when installing lock ring or injury to

personnel may result.

When installing lock ring, ensure the bulge is facing up or lock ring could unseat causing

serious injury to personnel.

Cracked, broken, bent or otherwise damaged rim components shall not be reworked, welded,

brazed, or otherwise heated or damage, injury or death may result.

No heat shall be applied to a multi-piece wheel or wheel component or damage, injury or

death may result.

(16)

Install lock ring (7) in lock ring groove (10) with bulge in lock ring (7) facing up.

Lock ring must be fully seated in lock ring groove around the entire circumference or lock

ring could unseat during tire inflation causing serious injury to personnel.

(17)

Check that lock ring (7), preformed packing (11), side ring (8) and wheel (13) are assembled correctly.

4-513

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |