|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2330-385-14

This task covers:

a. Alignment

b. Follow-On Maintenance

INITIAL SETUP

Tools and Special Tools

Personnel Required

Tool Kit, General Mechanic's

Two

(Item 49, Appendix J)

Materials/Parts

Jack, Stabilizer (2) (Item 23, Appendix J)

Chalk, Marking White (Item 9, Appendix E)

Jackstand (2) (Item 24, Appendix J)

Lockwasher (8) (Item 48, Appendix I)

Plumb Bob (Item 33, Appendix J)

Socket Set, 1 in. (Item 38, Appendix J)

Equipment Condition

Socket Set, 3/4 in. (Item 39, Appendix J)

Wheels chocked, (Para 2-20)

Tape Measurer (Item 47, Appendix J)

Front wheels removed, (Para 4-57)

Wrench, Impact Electric, 1 in. External

Drawbar level, (Para 2-23)

(Item 59, Appendix J)

(Item 62, Appendix J)

a.

Alignment.

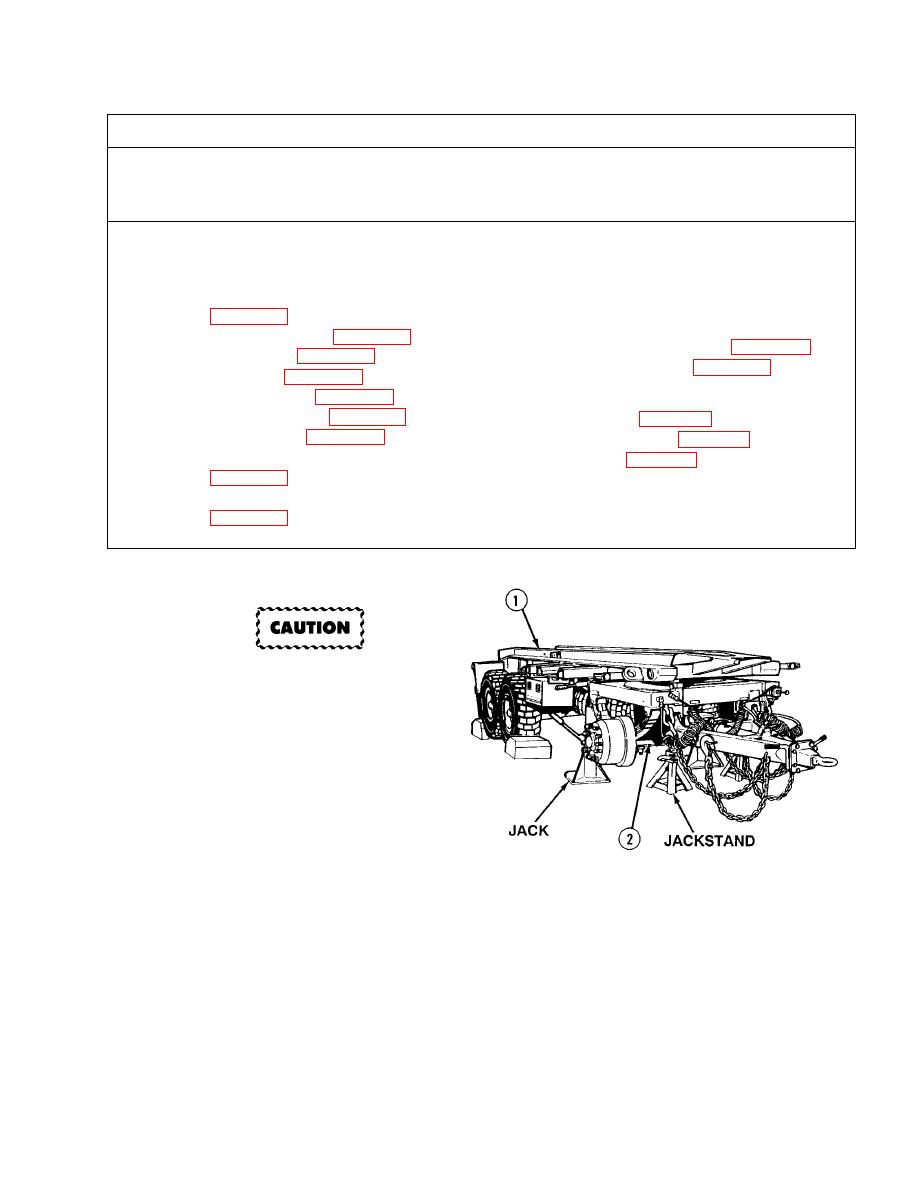

Trailer must be on a hard level

surface when performing axle

alignment. An uneven surface

could cause a misreading

resulting in an improper

alignment. Damage to

equipment could result.

NOTE

This procedure is used if Axle

No. 1 has been removed or

replaced, or as part of

troubleshooting.

(1)

Support trailer frame (1) with two stabilizer

jacks.

(2)

Remove two jackstands from under front

axle (2).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |