|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2330-385-14

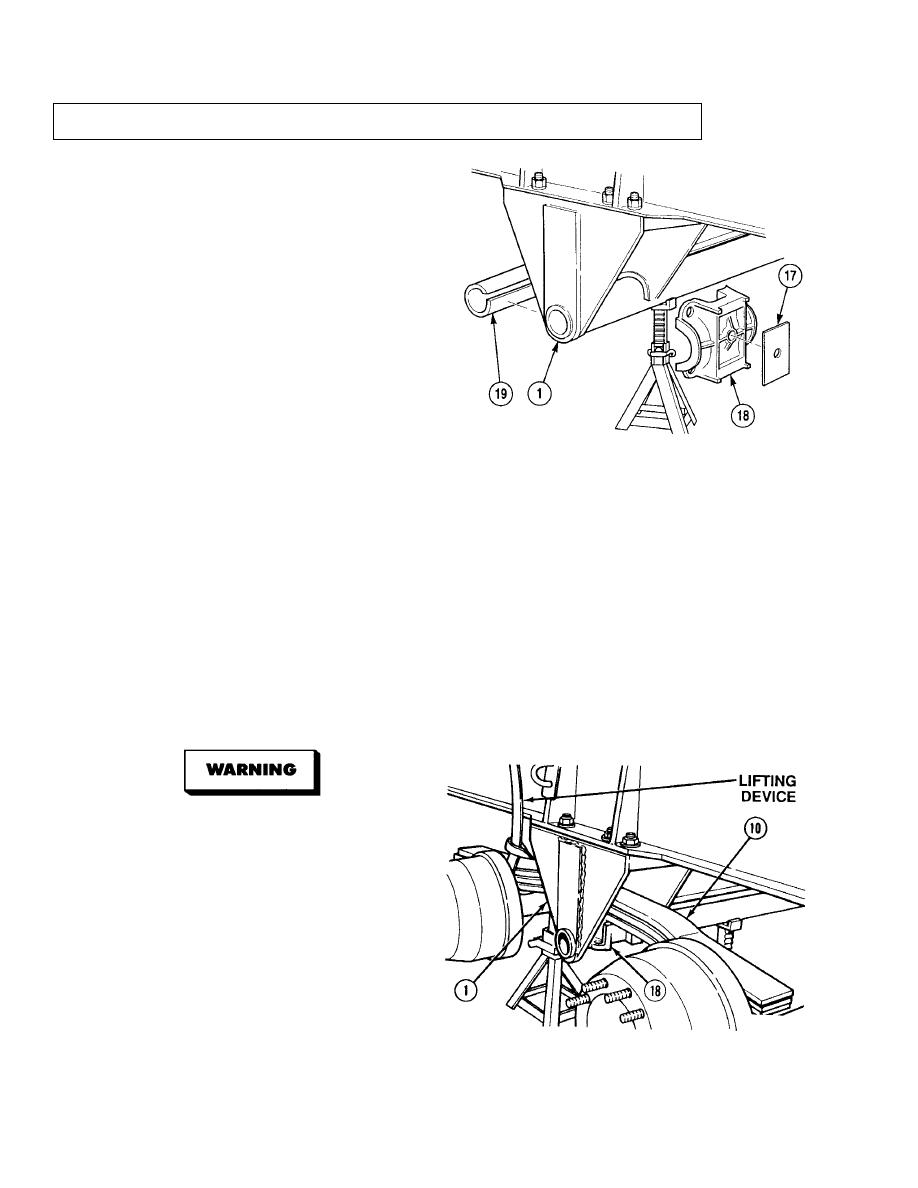

5-23. SPRING ASSEMBLY REPLACEMENT (AXLES NO. 2 AND 3) (CONT).

(13)

Remove liner pad (17) from upper trunnion

block (18). Discard liner.

(14)

Remove upper trunnion block (18) from

suspension hanger assembly (1).

(15)

Remove rubber bushing (19) from

suspension hanger assembly (1). Discard

rubber bushing.

b.

Installation.

NOTE

Tab on rubber bushing is

inserted in upper trunnion

block.

(1)

Install rubber bushing (19) on suspension

hanger assembly (1).

NOTE

Upper trunnion block is

installed over rubber bushing

and between two washers on

suspension hanger assembly.

(2)

Position upper trunnion block (18) on

rubber bushing (19).

(3)

Position liner pad (17) on upper trunnion

block (18).

Spring assembly weighs

approximately 240 lbs (109 kg).

Attach a suitable lifting device

prior to installation to prevent

possible injury to personnel.

(4)

Attach lifting device to spring assembly (10).

(5)

With the aid of an assistant, raise and

position spring assembly (10) on upper

trunnion block (18) by sliding rearward

through suspension hanger assembly (1).

(6)

Remove lifting device from spring

assembly (10).

5-82

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |