|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-3990-206-14&P

Section IV. UNIT MAINTENANCE PROCEDURES

This section contains Unit Maintenance procedures for the flatrack. These procedures may include servicing, hoisting,

inspection, cleaning, removal and disassembly, inspection, assembly and installation, adjustments and any procedures

needed for placing the flatrack or its components into service.

Servicing. The flatrack requires only lubrication and cleaning.

a.

b.

Hoisting Loaded Flatrack.

M1077 Flatrack weighs 3,200 lbs (1,453 kg) without side boards. M1077A1 Flatrack weighs

3,900 lbs (1,771 kg) without side boards. Attach suitable lifting device prior to removal or

installation to prevent possible injury to personnel.

(1)

For other than ordinary operation, flatrack must be secured and lifted with a crane or other suitable lifting

device. Normally, the flatrack is moved onto and off truck or trailer using LHS.

(2)

Install sideboards and straps before hoisting any load except an ISO container. Sideboards cannot be

installed with an ISO container.

(3)

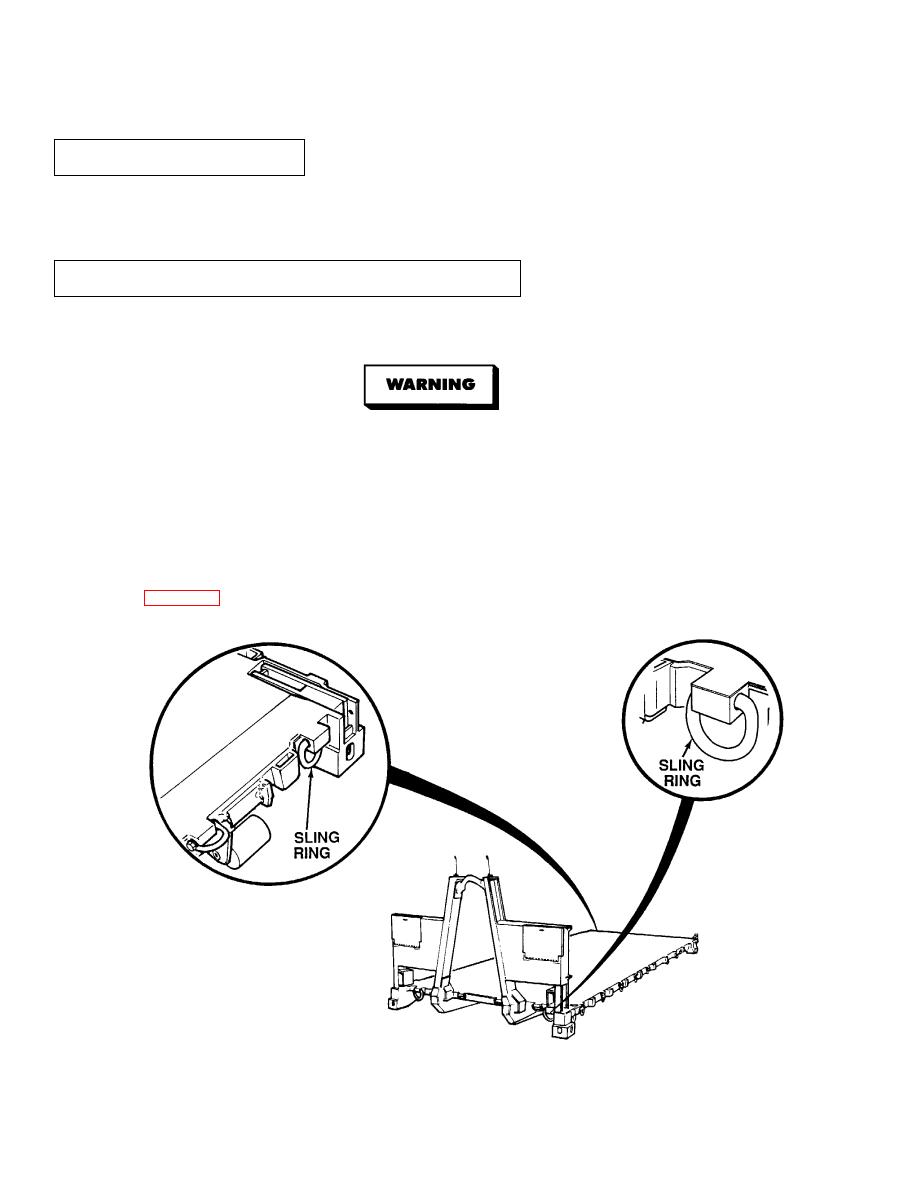

See Figure 4-2 for view showing sling rings. When lifting a loaded flatrack, use appropriate spreader bar

and chains to avoid side contact with load.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |