|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-3990-206-14&P

This task covers:

a. Disassembly

c. Assembly

b. Cleaning/Inspection

d. Follow-On Maintenance

INITIAL SETUP

Tools and Special Tools

Materials/Parts

Tool Kit, General Mechanic's: Automotive

Cloth, Lint-free (Item 4, Appendix E)

(Item 15, Appendix I)

Oil, Penetrating (Item 9, Appendix E)

Brush, Wire, Scratch (Item 1, Appendix I)

Solvent, Drycleaning (Item 14, Appendix E)

Compressor Unit, Air (Item 2, Appendix I)

References

Gloves, Chemical and Oil Protective

TB 43-0209

(Item 5, Appendix I)

TC 9-237

Goggles, Industrial (Item 6, Appendix I)

Gun, Air Blow (Item 7, Appendix I)

Equipment Condition

Sander, Disk Electric (Item 11, Appendix I)

Flatrack removed from truck

Torch Set, Cutting and Welding

and trailer prior to welding, (TM 9-2320-364-10)

(Item 16, Appendix I)

Welding Machine, Arc (Item 19, Appendix I)

a.

Disassembly.

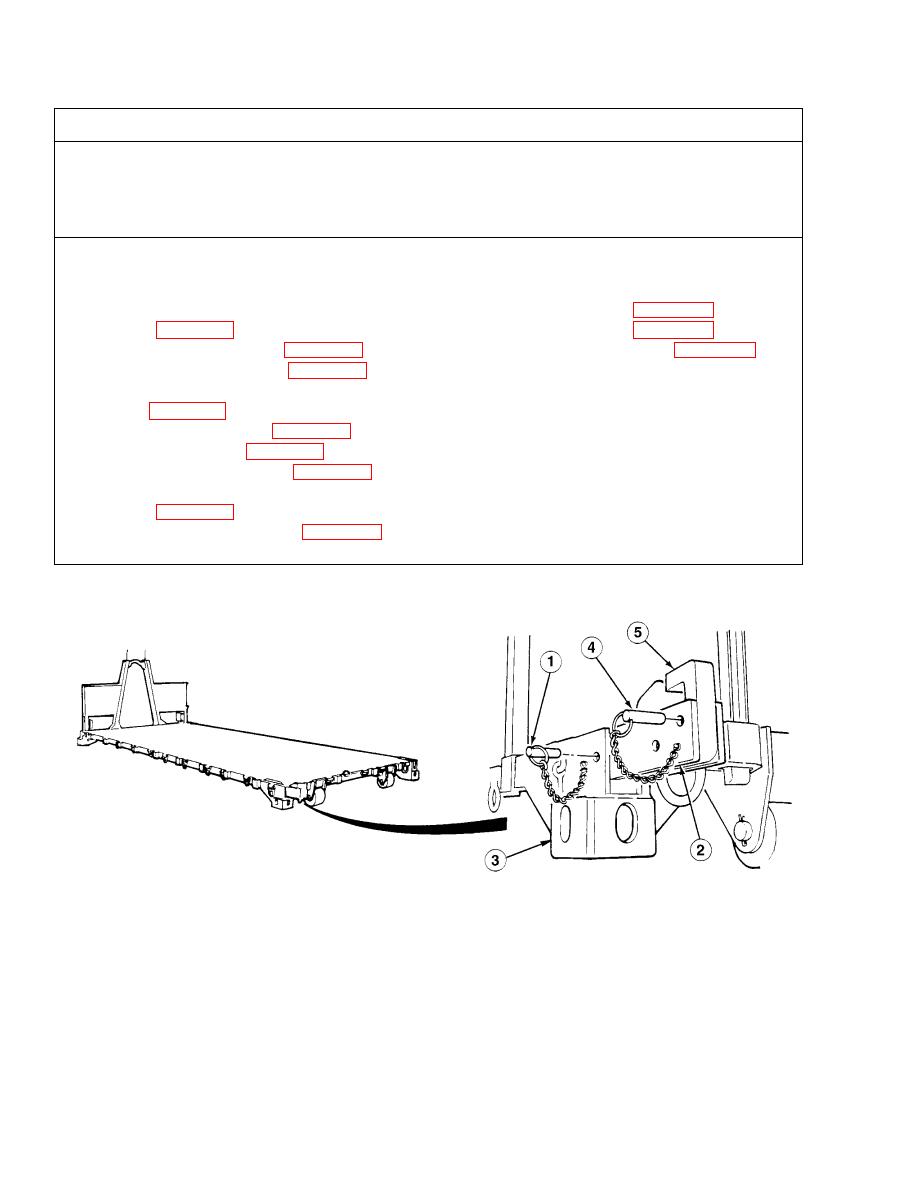

NOTE

This repair procedure applies only to later flatrack models. Early flatracks have the pivot

pin welded on both ends and are non-repairable.

Both left and right rear ISO locks are repaired the same way. Left rear ISO lock is shown.

(1)

Pull pin (1) from extension (2) and rotate extension out of flatrack (3).

(2)

Pull pin (4) from lock (5) and rotate lock out of extension (2).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |