|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-3990-206-14&P

1

2

3

1

3

3

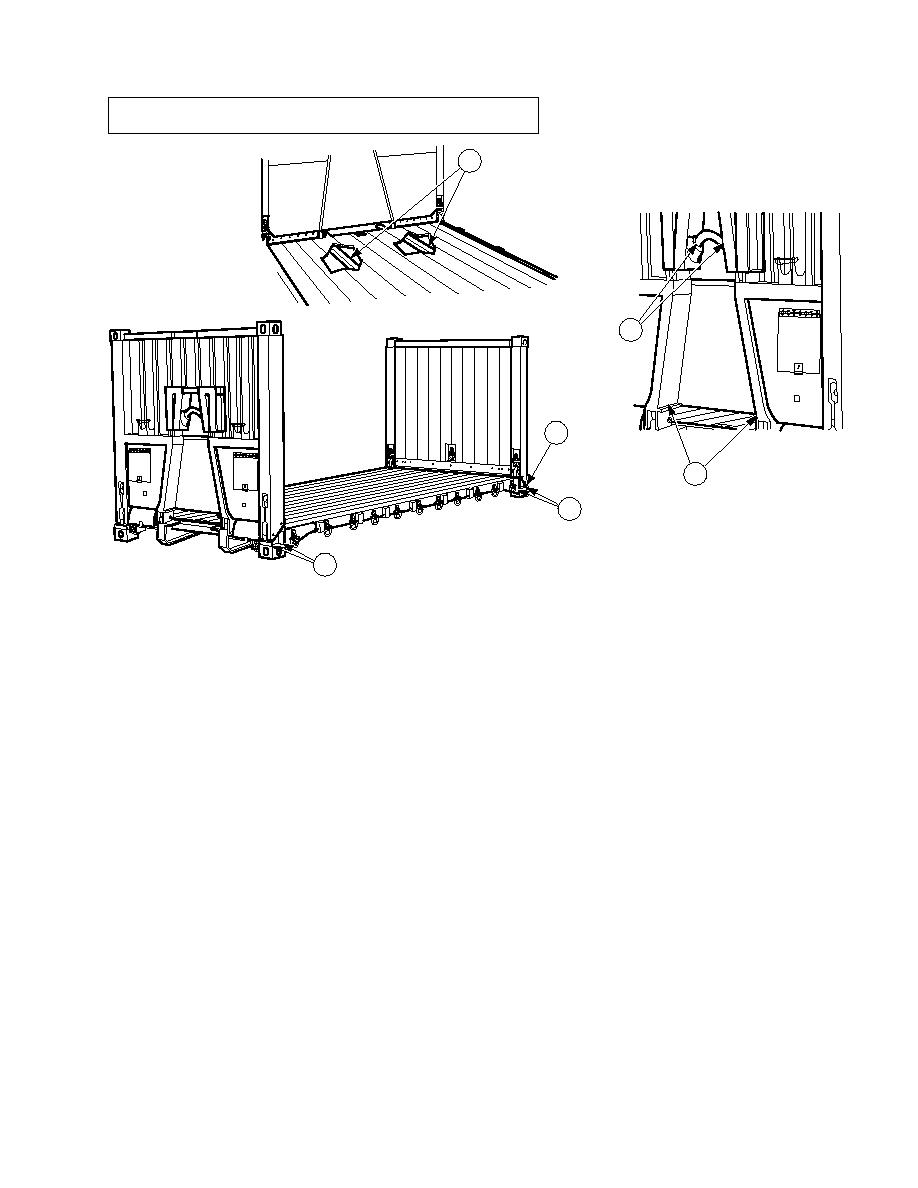

a. Weldment Points. Thoroughly inspect all weldments for cracks, chips or other damage. Areas include

the front and rear ISO locks, flatrack floor joints and wall, tiedown rings and the hookbar. Inspect welds for

cracks by doing ultra sound test or Zyglow inspection.

(1)

A-Frame Interface (1). This area includes the A-Frame channel to main rail interface, the top and

outboard wrapper plates, and the front wrapper plate and gussets. Solid welds in this area are necessary

to ensure safe loading and unloading of the flatrack.

(2)

Hookbar (2). These welds are located at the base of the hookbar casting on the A-Frame of the flatrack.

These welds secure the hookbar to the structure and are subjected to a significant portion of the total load

during loading and unloading operations.

(3)

Corner Fitting and Adjacent Structure (3). The corner fittings of the flatrack are used for transportation.

They may be used to secure the flatrack to a trailer, container or to another flatrack.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |