|

| |

TM 9-2320-364-34-2

12-31

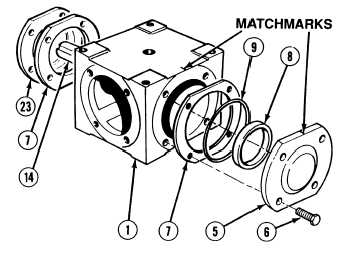

(7)

Apply lubricating oil to preformed

packing (9).

(8)

Install preformed packing (9) and bearing

cup (8) in closed end cap (5).

(9)

Install gasket (7) and closed end cap (5) in

housing (1) with four screws (6).

NOTE

When adjusting bearings,

ensure the number of

gaskets on each end does

not differ by more than one.

When making adjustments,

install and remove screws in

caps as necessary to get a

proper adjustment.

(10)

Add and/or remove gaskets (7) from closed

end cap (5) and open end cap (23) until

output shaft (14) turns freely by hand.

(11)

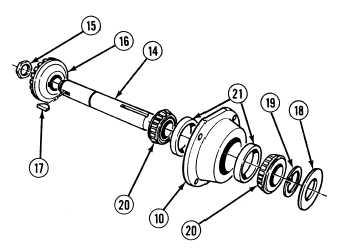

Pack two cone bearings (20) with grease.

(12)

Position two bearing cups (21), cone

bearings (20) in pinion housing (10).

(13)

Install pinion shaft (14) in pinion

housing (10).

Use care when installing

retaining rings. Retaining rings

are under tension and can act as

projectiles when released

causing injury to personnel.

(14)

Install retaining ring (19) and oil seal (18)

on pinion housing (19).

(15)

Install key (17) and bevel gear (16) on

pinion shaft (14).

(16)

Install crimped pinion nut (15) on pinion

shaft (14). Back crimped pinion nut (15)

off 1/4 turn and, using soft faced hammer,

hit end of pinion shaft (14) sharply to seat

bearings.

|