|

| |

TM 9-2320-364-34-3

16-29

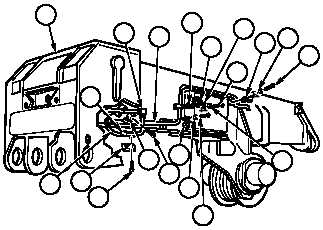

(81)

Remove three screws (163), spacers (164),

lockwasher (165), ground strap (166) and

three clamps (167) from front of boom base

section (4). Discard lockwasher.

(82)

Disconnect tube (168) from boom base

section (4).

(83)

Remove two screws (169) and clamp (170)

from boom base section (4).

(84)

Remove tube (171) from tube (162).

(85)

Remove two screws (172) retainer (173),

clamp (174) and tube (162) from boom

base section (4).

NOTE

Perform Steps (86) and (87) if data

plates are damaged.

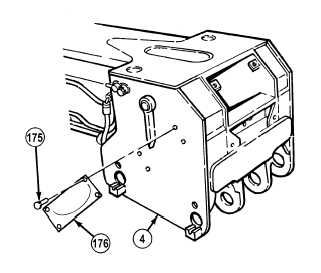

(86)

Remove four rivets (175) and angle data

plate (176) from boom base section (4).

(87)

Repeat Step (86) for remaining angle data

plate.

c.

Cleaning/Inspection.

Drycleaning Solvent (P-D-680) is TOXIC and flammable. Wear protective goggles, face

shield, and gloves; use only in a well-ventilated area; avoid contact with skin, eyes, and

clothes, and do not breathe vapors. Keep away from heat or flame. Never smoke when

using solvent. The flashpoint for Type II Drycleaning Solvent is 140 degrees F (60 degrees

C) and Type III Drycleaning Solvent is 200 degrees F (93 degrees C). Failure to do so may

result in injury or death to personnel.

If personnel become dizzy while using cleaning solvent, immediately get fresh air and

medical help. If solvent contacts skin or clothes, flush with cold water. If solvent contacts

eyes, immediately flush eyes with water and get immediate medical attention.

(1)

Clean metal parts in drycleaning solvent and inspect for cracks or wear.

(2)

Clean sheave assemblies and roller assemblies in drycleaning solvent.

(3)

Inspect brass bushings inside each assembly.

174

172

162

173

169

167

163

170

171

168

167

167

163

163

4

166

165

164

164

164

|