|

| |

TM 9-2320-364-34-3

16-106

16-14. HOIST BRAKE REPAIR (CONT).

Adhesives, solvents, and sealing compounds can burn easily, can give off harmful vapors, and

are harmful to skin and clothing. To avoid injury or death, keep away from open fire and use

in well-ventilated area. If adhesive, solvent, or sealing compound gets on skin or clothing,

wash immediately with soap and water.

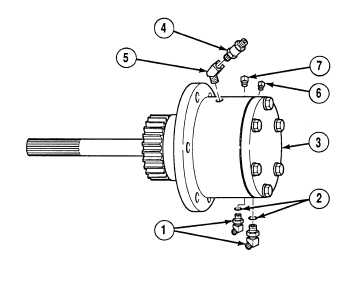

(18)

Coat threads of bleeder valve (7) with

sealing compound.

(19)

Install bleeder valve (7) and plug (6) in hoist

brake (3).

(20)

Coat threads of elbow (5) with sealing

compound.

(21)

Install and align elbow (5) in hoist brake (3).

(22)

Coat threads of check valve (4) with sealing

compound.

(23)

Install check valve (4) in elbow (5).

(24)

Apply hydraulic oil to two preformed

packings (2).

(25)

Install two preformed packings (2) on

elbows (1).

(26)

Install two elbows (1) on hoist brake (3).

e.

Installation.

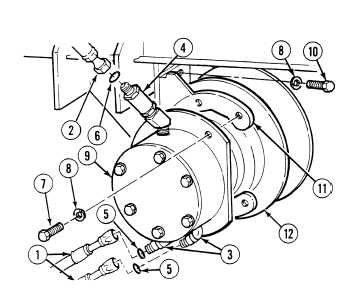

(1)

Align and install brake assembly (9) and

bracket (11) on hoist drum (12) with five

lockwashers (8), two screws (10) and three

screws (7). Tighten screws to 68 lb-ft

(92 N.m).

(2)

Apply hydraulic oil to preformed

packings (5) and (6).

(3)

Install two preformed packings (5) and

preformed packing (6) and connect hoses (1)

on two elbows (3) and check valve (4).

f.

Follow-On Maintenance:

Fill hoist brake, (TM 9-2320-364-20).

Load test crane, (Para 16-32).

Remove wheel chocks, (TM 9-2320-364-10).

END OF TASK

|