|

| |

TM 9-2320-364-34-4

20-302

Materials/Parts

Oil, Diesel Fuel (Item 32, Appendix B)

Oil, Lubricating (Item 36, Appendix B)

Gasket (Item 93, Appendix E)

Packing, Preformed (2) (Item 380, Appendix E)

This task covers:

a. Installation

b. Follow-On Maintenance

INITIAL SETUP

Equipment Condition

Timing and Synchronous Reference Sensor

installed, (Para 20-91)

Tools and Special Tools

Tool Kit, General Mechanic’s

(Item 240, Appendix F)

Wrench, Fuel Line (Item 270, Appendix F)

Wrench Set, Socket 3/8 in. Drive

(Item 273, Appendix F)

Wrench, Torque (0-60 N.m)

(Item 276, Appendix F)

Wrench, Torque (0 to 175 lb-ft [0-237 N.m])

(Item 277, Appendix F)

20-92. FUEL INJECTOR INSTALLATION.

a.

Installation.

NOTE

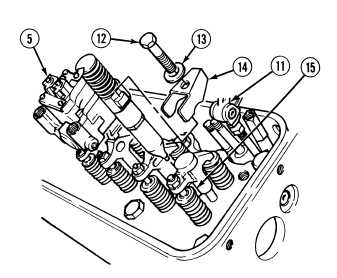

There are eight fuel injectors. All fuel injectors are installed the same way. Right side

shown.

Fill injectors with diesel fuel prior to installation.

(1)

Insert injector (5) into injector tube hole (15).

Do not force rocker arms all the

way back with shaft in place.

Failure to comply could result

in damage to push rods.

Ensure clamp does not interfere

with injector spring or valve

springs. Interference of clamp

with spring travel can cause

damage to components.

NOTE

Curved side of washer is installed

facing clamp.

(2)

Lift rocker arms (11) and install clamp (14),

washer (13) and screw (12). Tighten screw

20 to 25 lb-ft (27 to 34 N.m).

|