|

| |

TM 9-2320-364-34-4

20-327

Materials/Parts

Grease (Item 21, Appendix B)

Oil, Lubricating (Item 36, Appendix B)

Sealing Compound (Item 53, Appendix B)

This task covers:

a. Installation

b. Follow-On Maintenance

INITIAL SETUP

Equipment Condition

Engine lifting brackets installed, (Para 20-102)

Tools and Special Tools

Tool Kit, General Mechanic’s

(Item 240, Appendix F)

Gloves, Heavy Duty (Item 82, Appendix F)

Wrench, Crowsfoot, 9/16 in., 3/8 in. Drive

(Item 269, Appendix F)

Wrench, Torque (0-60 N.m)

(Item 276, Appendix F)

Wrench, Torque (0 to 175 lb-ft [0-237 N.m])

(Item 277, Appendix F)

20-103. TURBOCHARGER AND AIR INLET HOUSING INSTALLATION.

Materials/Parts - Continued

Wire, 16 Gage (Item 78, Appendix B)

Gasket (Item 73, Appendix E)

Gasket (Item 77, Appendix E)

Gasket (Item 113, Appendix E)

Gasket (Item 119, Appendix E)

Locknut (4) (Item 198, Appendix E)

Lockwasher (12) (Item 285, Appendix E)

Lockwasher (5) (Item 292, Appendix E)

Packing, Preformed (2) (Item 368, Appendix E)

Studs (Item 676, Appendix E)

a.

Installation.

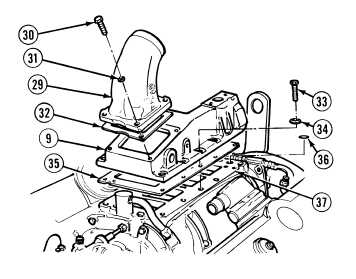

(1)

Apply lubricating oil to two preformed

packings (36) and install preformed

packings (36) on blower assembly

housing (37).

(2)

Apply grease to gasket (35).

(3)

Position gasket (35) on air inlet

housing (9).

(4)

Install air inlet housing (9) on blower

assembly (37) with ten lockwashers (34)

and screws (33). Tighten screws to

40 to 45 lb-ft (54 to 61 N.m).

(5)

Apply grease to gasket (32).

(6)

Position gasket (32) on air inlet housing

adapter (29).

(7)

Install air inlet housing adapter (29) on air

inlet housing (9) with four lockwashers (31)

and screws (30). Tighten screws to

16 to 20 lb-ft (22 to 27 N.m).

|