|

| |

TM 9-2320-364-34-4

25-87

c.

Cleaning/Inspection.

Drycleaning Solvent (P-D-680) is TOXIC and flammable. Wear protective goggles, face

shield, and gloves; use only in a well-ventilated area; avoid contact with skin, eyes, and

clothes, and do not breathe vapors. Keep away from heat or flame. Never smoke when

using solvent. The flashpoint for Type II Drycleaning Solvent is 140 degrees F (60 degrees

C) and Type III Drycleaning Solvent is 200 degrees F (93 degrees C). Failure to do so may

result in injury or death to personnel.

If personnel become dizzy while using cleaning solvent, immediately get fresh air and

medical help. If solvent contacts skin or clothes, flush with cold water. If solvent contacts

eyes, immediately flush eyes with water and get immediate medical attention.

(1)

Clean all metal parts with drycleaning solvent.

(2)

Inspect metal parts for breaks, cracks, burrs and sharp edges.

(3)

Inspect all bearings for wear, scoring and cracks.

(4)

Inspect split torque for broken splines and wear.

(5)

Inspect differential and bevel gear for broken splines and wear.

(6)

Inspect driven gear for broken splines and wear.

(7)

Inspect pinion shaft for broken splines and wear.

(8)

Replace all damaged parts.

d.

Assembly.

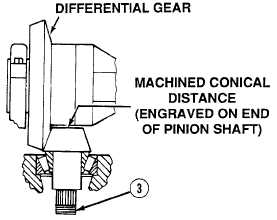

NOTE

Perform Steps (1) through (7) only if new pinion shaft and differential gear are being

installed.

The machined conical distance is engraved on pinion shaft head.

(1)

Record machined conical distance of used

pinion shaft (3) which was removed from

differential assembly.

(2)

Record machined conical distance of new

pinion shaft (3) which is to be installed in

the differential assembly.

(3)

Compare two distances recorded in Steps

(1) and (2). If distance recorded in Step (1)

is larger than distance recorded in Step (2),

proceed to Step (4). If distance recorded in

Step (2) is larger than distance recorded in

Step (1), proceed to Step (5).

|