|

| |

TM 9-2320-364-34-4

25-134

Materials/Parts

Adhesive (Item 1, Appendix B)

Sealing Compound (Item 56, Appendix B)

Sealing Compound (Item 60, Appendix B)

Solvent, Drycleaning (Item 68, Appendix B)

This task covers:

a. Removal

c. Cleaning/Inspection

e. Installation

b. Disassembly

d. Assembly

f. Follow-On Maintenance

INITIAL SETUP

Equipment Condition

Locking cylinders removed,

(Para 25-22 or 25-23)

Tools and Special Tools

Tool Kit, General Mechanic’s

(Item 240, Appendix F)

Gloves, Chemical Oil Protective

(Item 81, Appendix F)

Goggles, Industrial (Item 83, Appendix F)

Hammer, Hand, Soft Plastic

(Item 88, Appendix F)

Press, 60 Ton (Item 164, Appendix F)

Puller Kit, Universal (Item 174, Appendix F)

Socket, Socket Head Screw, 12 mm

(Item 206, Appendix F)

Torch, Propane (Item 247, Appendix F)

Wrench, Torque (0 to 175 lb-ft [0-237 N.m])

(Item 277, Appendix F)

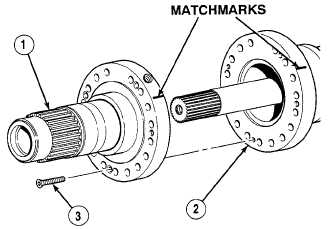

25-24. AXLE NO. 3 AND 4 SPINDLE REPAIR.

a.

Removal.

(1)

Matchmark spindle (1) and axle housing (2).

(2)

Remove two screws (3) from spindle (1).

Properly support spindle during

removal. Failure to comply may

result in injury to personnel.

NOTE

It may be necessary to use a soft

face hammer and tap on spindle

to break adhesive grip.

(3)

Remove spindle (1) from axle housing (2).

|