|

| |

TM 9-2320-364-34-4

27-17

(7)

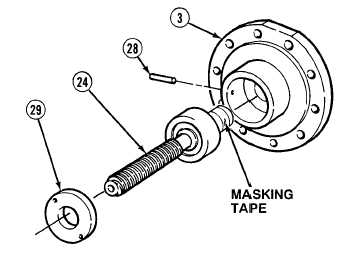

Wrap masking tape on splined end of

actuating shaft (24).

(8)

Position actuating shaft (24) in bearing

cap (3).

(9)

Install retaining nut (29) and locking

pin (28) in bearing cap (3).

(10)

Remove masking tape from actuating

shaft (24).

(11)

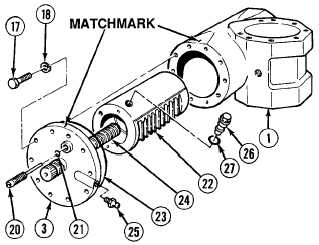

Apply hydraulic oil to preformed

packing (27).

(12)

Install preformed packing (27), valve (26)

on piston (22).

NOTE

Perform Step (13) if grease fitting

was removed.

(13)

Install grease fitting (25) in bearing cap (3).

(14)

Apply hydraulic oil to preformed

packing (23).

(15)

Install preformed packing (23) on bearing

cap (3).

(16)

Thread actuating shaft (24) and bearing cap

(3) into piston (22).

(17)

Position piston assembly (22) and bearing

cap (3) in gear housing (1).

Adhesives, solvents, and sealing

compounds can burn easily, can

give off harmful vapors, and are

harmful to skin and clothing. To

avoid injury or death, keep away

from open fire and use in a

well-ventilated area. If adhesive,

solvent, or sealing compound

gets on skin or clothing, wash

immediately with soap and water.

(18)

Coat threads of 10 screws (17) with sealing compound.

(19)

Align matchmarks and install bearing cap (3) on gear housing (1) with 10 lockwashers (18) and

screws (17). Tighten screws to 20 to 30 lb-ft (27 to 41 N.m).

(20)

Apply hydraulic oil to preformed packing (21).

(21)

Install preformed packing (21) on valve (20).

(22)

Install valve (20) in bearing cap (3). Tighten valve six turns.

|