|

|||

|

|

|||

|

Page Title:

ONE OR BOTH FLATRACK LOCKING MECHANISM LATCHES WILL NOT UNLOCK OR REMAIN UNLOCKED. |

|

||

| ||||||||||

|

|

TM 9-2330-385-14

4-15. AIR SYSTEM TROUBLESHOOTING PROCEDURES (CONT).

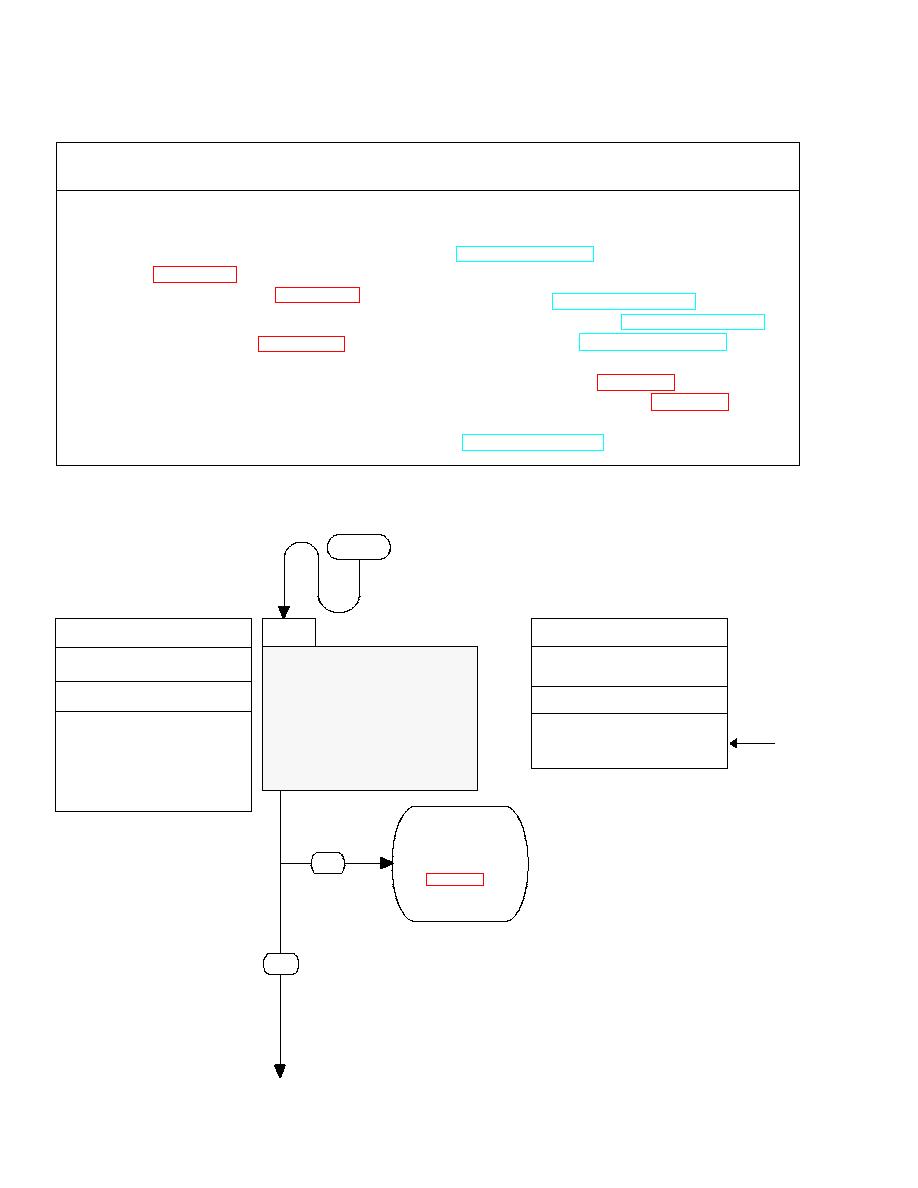

3. ONE OR BOTH FLATRACK LOCKING MECHANISM LATCHES WILL NOT UNLOCK

OR REMAIN UNLOCKED.

INITIAL SETUP

Tools and Special Tools

References

Tool Kit, General Mechanic's: Automotive

TM 9-2320-364-10

(Item 50, Appendix J)

Equipment Condition

Pressure Test Kit (Item 34, Appendix J)

Engine OFF, (TM 9-2320-364-10)

Parking brake applied, (TM 9-2320-364-10)

Materials/Parts

Wheels chocked, (TM 9-2320-364-10)

Solution, Soap (Item 21, Appendix E)

Emergency and service air supply gladhand

Personnel Required

connected to truck, (Para 2-22)

Two

Trailer air system charged, (Para 2-22)

Flatrack removed from trailer,

(TM 9-2320-364-10)

NOTE

Soap and water solution will be used to visually check for leaks.

START

1.

KNOWN INFO

TEST OPTIONS

Visual inspection.

Truck air system OK.

Are air lines 2078, 2080, 2081,

Audible inspection.

fittings, pressure holdback

valve, flatrack locking valve

POSSIBLE PROBLEMS

REASON FOR QUESTION

and air chambers free of

leaks?

If lines and/or components leak,

Air lines and fittings faulty.

locking mechanism latches will

Pressure holdback valve faulty.

not unlock.

Flatrack locking valve faulty.

Air chamber(s) faulty.

Flatrack mechanism

components faulty.

Tighten loose fittings,

repair or replace air

lines and/or fittings

NO

and components

Verify repair, go to

Step 6 of this Fault.

YES

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |