|

|||

|

|

|||

|

Page Title:

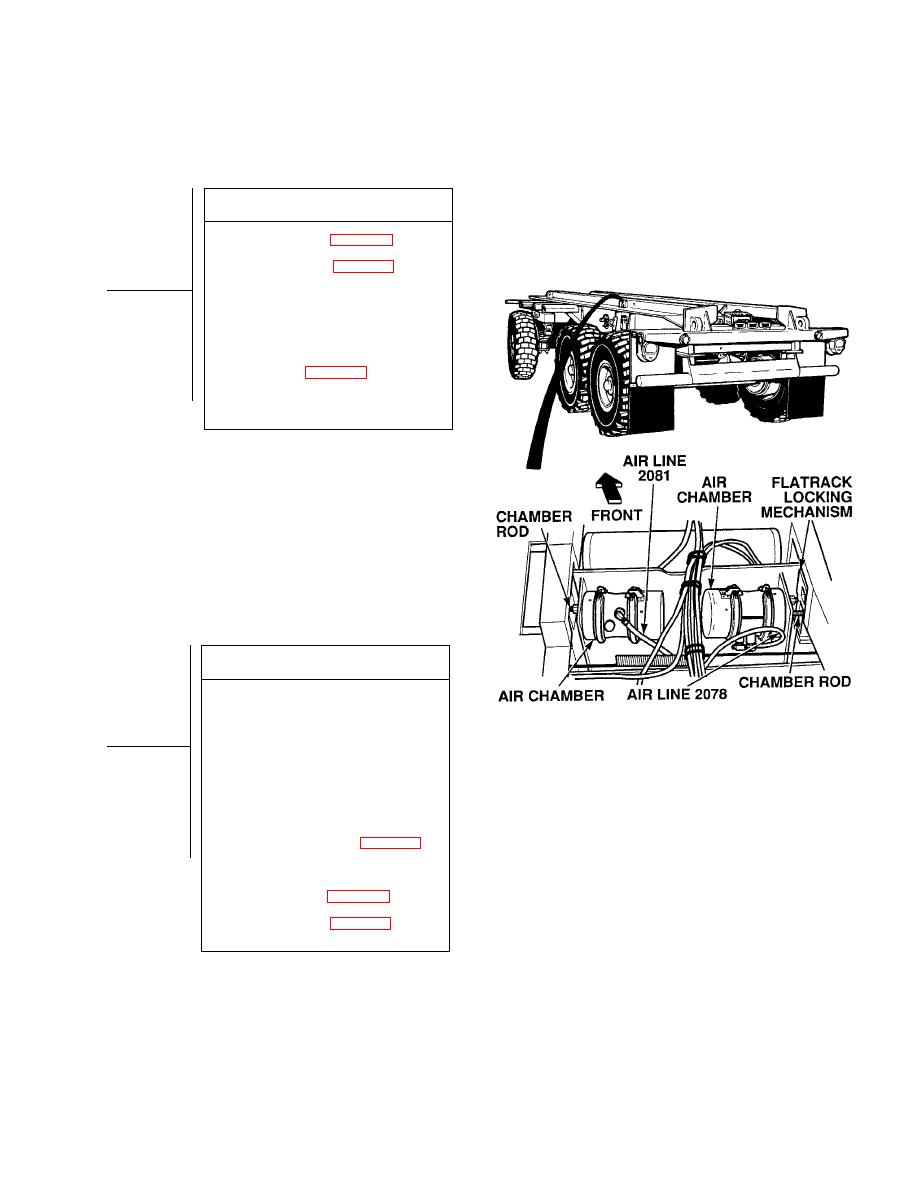

ONE OR BOTH FLATRACK LOCKING MECHANISM LATCHES WILL NOT UNLOCK OR REMAIN UNLOCKED. (Cont) |

|

||

| ||||||||||

|

|

TM 9-2330-385-14

AIR CHAMBER OPERATION TEST

(1) Cage air chamber (Para 4-65).

(2) Remove upper locking pin from

air chamber clevis (Para 4-67).

(3) Uncage air chamber.

(4) While assistant pushes in flatrack

locking valve, observe air

chamber operation.

(a) If air chamber rod does not

move in chamber, perform

Step (5) below and replace air

chamber (Para 4-67).

(b) If air chamber rod moves in

chamber, air chamber is OK.

(5) Pull out flatrack locking valve.

VISUAL INSPECTION

(1) Visually inspect locking mechanism,

looking for bent, broken and/or

rusted components.

(2) Operate locking mechanism by hand;

ensure that locking components move

freely and do not interfere with each

other.

(a) If locking components are

damaged or do not operate freely,

perform Steps (3) through (5)

below and replace damaged

locking components (Para 4-66).

(b) If locking components are not

damaged and operate freely,

locking mechanism is OK.

(3) Cage air chamber (Para 4-65).

(4) Install upper locking pin in

air chamber clevis (Para 4-67).

(5) Uncage air chamber.

4-223

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |